PRESIDENT’S LETTER: New Executive Director

Kevin Wensel, Omega Products International

There are some big changes going on at the SMA. Our Executive Director Norma Fox informed the Board earlier this year that she would be retiring at the end of this year. Norma has been the ED of SMA for more that eighteen years. She has been a mentor, friend, and confidant to many members of the Association. Norma has been all three of those things for me, as the president of the SMA for the last two years. This is the first time I have been active in a trade association board, so she took me under her wing — helping me understand and execute the duties and responsibilities of the presidency. Generally, she was kind about it, but (as many of you probably experienced, too) she has no issue kicking you in the butt if she feels it is necessary. Though in everything she did for the Association, she did it from a place of caring. Norma genuinely cares about the Association and the members of it. We are going to miss her greatly. I wish her the best on her much deserved retirement!

After Norma gave her notice, the Board started the search for a new Executive Director. We meet a number of times to put together the requirements for the position and a plan for identifying candidates. It became clear to the Board that Mark Fowler of Mark Fowler Associates would be the ideal candidate for the ED position. Mark has a great balance of plastering, architectural, and industry trade group experience. With his plaster industry experience and connections, Mark will help the SMA become a truly national organization and authority in the plaster industry. Welcome, Mark!

MEET THE NEW SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

The new SMA Executive Director is Mark Fowler. Mark grew up in Southern California in the plastering business. His father owned Oz Fowler Plastering and was well known in Orange County for interior gypsum plaster when plaster was still king and then cement stucco in the 70’s lath and plastering thousands of tract homes.

Mark went to college, majoring in Architecture, but soon found plastering was more lucrative. Times have changed. He was also a member of the old Local #2 Plasterers Union from Los Angeles. He ran gun crews, finish crews, estimated and eventually became general manager. Mark then moved to Seattle and worked for Imasco Minerals, a Canadian stucco manufacturer. He quickly moved to the Northwest Wall and Ceiling Bureau (NWCB) where he was instrumental in developing the Stucco Resource Guide and many of the technical bulletins for the NWCB. Mark developed a strong relationship with architects and the building officials in the Northwest. He presented at conventions, trade shows and educational seminars, such as the first EIFS and Stucco certification programs in the United States.

He then worked as a project manager for Soltner Group Architects of Seattle. While there he managed several large multifamily projects and focused on exterior envelopes and AAMA water-testing protocols. Mark also was connected with several projects that involved water leaks, cement stucco and eventual litigation.

“Mark will be a great benefit to the Stucco Manufacturers Association. His connections and respect among the designers and architects are well known,” said Keith Soltner AIA.

Fowler spent the last eight years at the Western Wall and Ceiling Contractors Association where he handled labor negotiations, spearheaded the publication of the Plaster and Continuous Insulation Brochure and the Plaster and Drywall Assemblies Manual.

If the name sounds familiar, he has been the Editorial Director for Walls and Ceilings Magazine since 2006. With a monthly editorial page and several published articles, as well as guest speaker at various events, Mark is well known in the stucco and plaster industry.

Mark is looking forward to working with the members of the SMA to reach the strategic growth goals established in 2014 by the SMA board of directors. These goals include greater national presence and growth through education and technical excellence.

“Stucco is a unique and fantastic cladding that others can only wish they match,” said Mark Fowler. “This is why it is under attack so often and why we need to promote stucco and plaster by just telling the truth.”

PLEASE NOTE: NEW SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

SIGN UP NOW FOR OUR NOVEMBER 18 LUNCH MEETING

NORMA (WE WILL MISS YOU)

The SMA and all the members want to wish Norma Fox a well-deserved retirement as she leaves us on November 1. She deserves a pleasant and relaxing retirement for all her years of dedicated service to our industry. Norma took the helm of the SMA in 1998 and has done a great job of managing the stability of the SMA. This included herding the directors and keeping them on a focused tracK to get things done. This is no easy task, as we all know the personalities in our business are pretty strong willed, but Norma kept the SMA alive and well. This is even more amazing when one thinks of the tough times our industry has had to endure. Her leadership kept stucco moving forward in the face of attacks, as it still remains a leader in cladding to this day. We will miss Norma’s distinct and unique personality at future SMA meetings.

A Little About Our Norma:

Norma is originally from Bayonne, New Jersey. She is a proud graduate from the Fashion Institute of Technology in the heart of Manhattan. She moved to Southern California 32 years ago from NJ and started her own Association Management Co. Her first client was the California Film Extruders and Converters Association (CFECA). This became the launching pad for an illustrious career in association work. Somehow it is not hard to believe that association management work and Norma were just kind of made for each other. She was awarded the CFECA highest honor for her efforts in growing the association. This success led to more associations wanting her personality and leadership abilities. At one point, Fox Association Management Services Inc. with a staff of 2 was running eight associations. She was also the first executive director of the Plastering Contractors Association. Norma was the first executive director of the Forensic Expert Witness Association, which started as a local group and she grew them to 9 chapters and a national association. Norma (Rubenstein) Fox was always up for a challenge and met those challenges head on with the right blend of her humor, honesty and that directness needed for the job she did so well.

Her retirement will be filled with family and doting over her two grandsons, Reilly Evan (8) and Asher Yona (3 1/2). Norma is very proud of her daughter, Dr. Lauren Fox MacMillan who is a Gereatric Psychologist and her son-in law Daniel MacMillan. Fortunately they live in southern California so Norma will be able to spend quality time with her family. All of us want to thank Norma and wish her all the best in her well-deserved retirement. On to another chapter in her life.

SMA GOLF TOURNAMENT IS ANOTHER HUGE SUCCESS

The rains cleared, the sun came out and the day was perfect for the record number of golfers who showed up to play at Strawberry Farms. The third annual SMA golf event went off without a hitch and produced a record attendance. SMA Executive Director Norma Fox did a great job and was grateful for the help that Stephanie Allgood from Dryvit, Jeff Becksted of Hunter Panels, and Tina McIntyre of TXI Riverside cement provided to set things up and handle registration. Tyler Parker of BMI helped with the dinner and awards.

The food and staff at Strawberry Farms were great. Kevin Wensel, the President of SMA, started the awards program with an announcement that the November SMA meeting will be a very special meeting as it is also a retirement party for beloved SMA Executive Director, Norma Fox. Norma has served the SMA for nearly two decades and the membership wants to send her off to retirement with a party she truly deserves. Please plan to attend this meeting on November 18 and please make your reservation and prepay online. Mark Fowler, the new Executive Director, will be introduced as well.

Rui Bronze of BMI, and an SMA board member and treasurer, took over as the MC and kept the group lively. He did a great job with the auction of some fabulous raffle prizes. The prizes were donated by members and sponsors. A good portion of the proceeds went to the Wounded Worrier Foundation.

PRIZE WINNERS

The winning score for the golf tournament was a team 56.

FIRST PLACE: Brad Stevensen, Larry Smith, Able Gonzales, Albert Gonzales

SECOND PLACE: Tom Blythe, Gil Villela, Jeff Swanson, Tom Aldana

THIRD PLACE: Matt Chila, Paul Maag, Max Carreon, TJ Gillen

LONGEST DRIVE: Mike Kiefer

CLOSEST TO THE PIN: Jose Castellon and Jeff Swanson

THANK YOU TO ALL OUR GOLF TOURNAMENT SPONSORS!

Gold Sponsor: Omega Products International

Silver Sponsors: BMI Products Inc., Parex USA, P.W. Gillibrand Co. Inc., Riverside Cement, L’Hoist, N.A., Merlex Stucco Inc.

Bronze Sponsors: Fortifiber Building Systems Inc., Dryvit Systems Inc., Accent Building Materials, Del Mar Plastering Inc., Stockton Products, Structa Wire Corp.

Hole/Green Sponsors: Accent Building Materials, Akzonobel Performance Additives Group, BMI Products Inc., Del Mar Plastering Inc., Dryvit Systems Inc., Fortifiber Building Systems Inc., L’Hoist, N.A., Merlex Stucco Inc., Omega Products International, P.W. Gillibrand Co Inc., ParexUSA, Riverside Cement, Stockton Products, Structa Wire Corp., Horn Company, Cemex

WELCOME NEW MEMBERS

Horn Coatings and Building Materials

SMA welcomes new stucco supplier member Horn Coatings and Building Materials, and their representative Jay Umphrey in La Mirada. Please see the SMA Member Directory for their company/contact information.

SMA welcomes new stucco supplier member Horn Coatings and Building Materials, and their representative Jay Umphrey in La Mirada. Please see the SMA Member Directory for their company/contact information.

Wallcare Technology Development Co. Inc.

SMA welcomes our new international member Wallcare Technology Development Co. Inc., and their representative Naomi Zhao in Nanjing, China. Please see the SMA Member Directory for their company/contact information.

SMA welcomes our new international member Wallcare Technology Development Co. Inc., and their representative Naomi Zhao in Nanjing, China. Please see the SMA Member Directory for their company/contact information.

FEATURE ARTICLES

Code Updates

SMA contractors will want to pay attention Section 2510.6 of the International Building Code as it may impact your projects with regard to lathing. New code language has been placed in the code with regard to installing building papers and home wraps. In particular when installed over wood based sheathing for cement stucco cladding. The following is the new language from the International Building Code:

2510.6 Water-resistive barriers.

Water-resistive barriers shall be installed as required in Section 1404.2 and, where applied over wood-based sheathing, shall include a water-resistive vapor-permeable barrier with a performance at least equivalent to two layers of Grade D paper. The individual layers shall be installed independently such that each layer provides a separate continuous plane and any flashing (installed in accordance with Section 1405.4) intended to drain to the water-resistive barrier is directed between the layers.

This new language will likely create some confusion as it changes the way most contractors have installed two-ply building paper for decades. The new language essentially is intended to move the drainage plane from between the WRB (Water–Resistive Barrier) and the cement stucco to between the two layers of WRB. In addition, the language instructs contractors to install each layer of WRB independently of each other. This is contrary to the traditional method of applying two layers WRB at the same time.

Manufacturers of asphaltic paper have produced two-ply products for decades. These two-ply products have proven to be effective and functional. The change in code language may raise concerns and confusion. The SMA committees will be addressing these issues and likely be making some proposals for consideration. For comments to the committee reviewing this policy, feel free to send your comments to the SMA office.

WRB on SOFFITS AND CEILINGS

This is another code issue popping up for stucco contractors. A change in code language led some to believe an omission of specific language, means a requirement has been set. The old Uniform Building Code specifically stated that building paper could be eliminated from ceilings or soffits that were to receive cement plaster. This practice was common as contractors routinely used lath products specially and sometimes solely designed for soffit installations. These lath products rarely had paper backing, and it was typically only a backing intended to prevent cement blowing through when using plaster pumps. The new code language moved from prescriptive to more performance-based and left out the WRB (Water-Resistive Barrier) exclusion on soffits. This has led some designers to wonder if a WRB is now required on ceilings and soffits. Generally there is no benefit to a WRB on a soffit or stucco ceiling. Most experts prefer not to have a WRB on the ceiling under stucco. WRB is used on walls to prevent water intrusion to framing members. However, on a ceiling the WRB could potentially prevent water from easily escaping or being absorbed and then diffusing through the stucco membrane. While it is not a code violation to install a WRB on the cement plaster ceiling, it is typically not recommended.

It is important to keep up with code and industry trends for cement stucco design and installations. Contact your local supplier, manufacturer or the SMA office for any further information.

FLORIDA

The state of Florida Building Commission has produced a declaratory statement on cement stucco, in particular on the application of cement basecoats. The statement reads:

“Stucco applied per ASTM C 926 as permitted under the Exception to Section 703.6.4 , compliance with the minimum application intervals between stucco coats is not required.”

This means the requirement for a 48 hours cure time period between the scratch and brown coats may be shortened as per allowed by ASTM C 926. ASTM C 926 states that the scratch coat shall become sufficiently rigid prior to applying the brown coat. This has been referred to this as the “double-back” method. Ironically, the double-back method was part of the Uniform Building Code, and similar to the WRB on soffits issue. The code language was dropped, which led some to believe it is no longer valid or allowed. The state of Florida has clarified the language is still valid. The SMA acknowledges the efforts by the Florida Lath and Plaster Bureau (www.flapb.com) for spearheading this campaign to better the industry. The SMA also supports the statement by the Florida Commission.

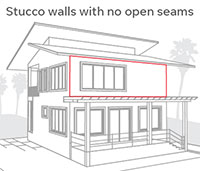

Stucco and Porosity

Stucco is a blend of Portland cement, lime and aggregates, none of which is negatively impacted by the presence of water. In fact, the mix that makes Portland cement plaster will strengthen over time when exposed to water. The benefits of cement stucco make it a favored cladding for building exteriors because it is highly water resistant, noncombustible, pest resistant, durable, low maintenance and capable to be seamless even in radius surfaces.

One myth that continually pops up is that cement stucco cladding is porous.

POROUS: Defined as a material having small holes that allow air or liquid to pass through.

AIR: The International Energy Conservation Code (IECC) under section C402.4.1.2.2 Assemblies, item number 2, lists a Portland cement/sand parge, stucco or gypsum plaster having a minimum thickness of 1/2 inch (12mm) as an air barrier assembly compliant to the IECC. Cement plaster is therefore not porous to air per the code.

WATER: While cement plaster will absorb water, the water will not pass through properly mixed and applied cement plaster. Independent third party studies confirm this fact:

- FEDERAL TESTING LABS (1996): Test Report No. 96-3484. This independent test used mixes compliant to ASTM C 926. Application was 3/4 inch thick basecoat (scratch and brown) with no finish coat applied. All panels were 3/4 inch thick cement and moist cured for 24 hours. Water testing was done 29 days after cement application, simulating a moderate wind-driven rain per ASTM E514. The water volume was 112 gallons per hour and sprayed continuously for two hours at the same location on the panels. The back of the plaster cement was exposed and no panel exhibited any sign of water seepage during or after the test. Similar tests were conducted in the 1970s in southern California with similar results. The Federal Lab test was sponsored by the Northwest Wall and Ceiling Bureau, and the full report is available by contacting the SMA or NWCB.

- NCMA RESEARCH AND DEVELOPMENT LABORATORY (2007) Project No. 05-466B. The test was to determine water resistance of cement plaster (stucco) over masonry units. Thirteen walls were constructed with various cement thicknesses over standard Concrete Masonry Units (CMU) One wall had no stucco applied to the CMU and was a control wall. Mixes were all ASTM C 926 compliant and water testing was done per ASTM E 514. The walls with skim coats of 1/8, 1/4 and 1/2 inch cement plaster resisted water penetration for up to four hours. The control wall, no stucco applied, leaked in 30 minutes.

- Hurricane. The NCMA then decided to test at levels representing a hurricane condition. The wind was increased to 155 and 180 mph. The results concluded that all cement plaster resisted water penetration at low to moderate wind pressures. The 1/8 inch skim coat kept water out at lower wind speeds. The 1/2 inch cement coatings resisted water entry even at 155 mph, and only minimal water leakage at 180 mph after 24 hours of continual water spray. The full report is available from the Florida Lath and Plaster Bureau or the SMA.

Both tests for water and the code statement on air verify that properly mixed and applied cement plaster (stucco) is not porous.

PRESS RELEASES FROM OUR MEMBERS

Plastic Components receives important approval on Ultra-Lath Plus®

Plastic Components Ultra-Lath Plus® HDPE Lath has a service history of over 16 years. Ultra-Lath® has gained a following in coastal climates and other extreme environments where rusting of the stucco reinforcing can be a concern. Available in sheets or rolls, new Ultra-Lath Plus® is now recognized as an alternative to metal reinforcement for stucco under the IBC and IRC. In addition to rust resistance, Ultra-Lath Plus® offers several application and performance benefits:

- Self-furred 1/4” for positive keying of the stucco

- Fully resistant to the harsh chemicals found in cement-based products

- Does not rely on alkali resistant coatings for performance

- Cuts easy for faster installed costs

- Lightweight for easy transport to the jobsite

One limitation of plastic lath has been concerns over fire resistance. Plastic Components has passed the rigorous NFPA 285 multi-story fire test. Passing this fire test allows plastic lath by Plastic Components to go beyond basic Type V construction. Master Wall Inc.® recognizes the use of Ultra-Lath Plus® as an approved alternative for vertical applications of our Cemplaster Fiberstucco System 3/4” and above and will recognize specific alternative installations on a case-by-case basis. This approval is subject to the limitations in Plastic Components’ code report, local jurisdictional building authority acceptance and designer/owner acceptance.

Plastic Components products are available at most Master Wall® distributor locations. To learn more visit www.plasticcomponents.com

.