FROM THE EXECUTIVE DIRECTOR: Planning a Future for the Growth of Stucco and Plaster

Mark Fowler, SMA Executive Director

Your SMA committees have been hard at work creating documents and strategic planning a future for the growth of stucco and plaster. There are four committees and all SMA members may participate.

ONE COAT: This committee is working with the National One Coat Stucco Association. Project items include working on a large-scale fire test, revising Continuous Insulation protocols, a planned joint meeting with our friends in Texas, and methods to better harmonize and consolidate Evaluation Reports and ASTM standards for one coat.

THREE COAT: This committee has finished a generic three-coat guide specification for cement stucco. Architects and design firms across the United States have been asking for it and the SMA is delivering. This will be the most up to date and comprehensive specification available. The committee has also produced a letter defining and clarifying the differences between EIFS, One and three-coat stucco. This was needed as a response to EIFS exclusion riders with erroneous definitions of stucco.

Another important paper is the SMA position on flashing guidance for a nail-flange window. While the procedure is the same as AAMA and ASTM, the SMA paper goes a step farther to clarify options between the stucco assembly and the window frame for nail flange style windows. The paper has caveats and several options to assist designers and contractors.

TRIM ACCESSORIES: This committee has created a document on impacts of cement in contact with aluminum and corrosion issues, due to be released soon. The committee has a slate of issues to work on regarding reveals, and attachments of accessories. Meetings to start this Fall.

MARKETING: The 2016 US stucco market share report has been well received. Calls and inquiries have been coming in from around the United States. Most agree that it has drawn needed attention to the concerns that plastering needs more attention in marketing efforts. Your SMA marketing committee is currently gathering data to improve and expand next year’s report.

If you have interest in participation in any of the committees, let the SMA office know. Most meetings are online and simply require logging in.

SMA RELEASES GUIDE SPECIFICATIONS FOR THREE-COAT STUCCO

Architects have been calling the SMA offices for guide specifications and details on three-coat stucco. The SMA has responded with generic specifications suitable for the entire United States. These specifications on generic three-coat stucco have the backing of manufacturers of the stucco products installed by the lath and plastering contractors. These are up-to-date specifications that are available in Word format. Products are specifically listed in generic terms. There will be two guide specifications for designers to select from: One is for cement stucco over framing members and the other specification is for cement stucco over concrete or masonry substrates.

Architects and builders can feel confident these new specifications are intended to provide a cost effective installation and minimize RFIs and avoid costly change orders when specifying cement stucco. The new specifications allow for options by the designer and helpful tips on making the best selection for your particular project using cement stucco.

RAINSCREEN: Cement stucco over framed and masonry substrates have proven themselves long lasting and aesthetically appealing in all climates around North America. The option of enhanced drainage is an option for designers to consider. Rainscreen is not required or necessary to assure cement stucco will work as a serviceable cladding. Projects in Chicago, New York and even Seattle are working just fine. Good design, basic flashings and quality installations are your best assurance to code compliant stucco. Rainscreen is an optional upgrade, unless mandated by local Building departments.

SMA RELEASES FLASHING RECOMMENDATIONS FOR NAIL-FLANGE WINDOWS

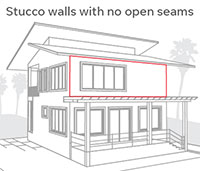

Nail-flange style windows have been around for over forty years in the residential market. Many have been installed in structures that are clad with cement stucco. A debate on the issue of how to treat stucco termination around the window frame continues. The SMA taskforce spent a considerable amount of time researching the issue for Code compliance, past performance and suitability for today’s more airtight structures. The committee also reviewed the newest requirements by the American Architectural Manufacturers Association (AAMA) to insure compliance with the code and standards.

The SMA developed a flashing procedure that is based on AAMA and ASTM procedures. These procedures are well established and stop short on the recommendation for a casing bead and sealant around windows. The SMA has taken position to provide assurance for developers, designers, code authorities and contractors. The SMA paper and procedure is available as a free download on the SMA website under “Technical Resources: Details.” All four pages must be used and each step for flashing is critical for success.

These papers published by the SMA have significance for design and installation. The SMA has been in existence since 1957 and code authorities recognize SMA publications. The SMA works hard to produce industry relevant and consensus documents that provide an approved industry practice and standards for best practices. The SMA has no intention or desire to challenge any code language, restrict options or limit creativity. In most cases this is to enhance or clarify the manufacturer’s intent on how their products should be installed. There are a few instances were the SMA will provide an “Alternative” to prescribed code language. This may seem incongruent with traditional policy: however, the Building Code specifically allows for alternatives to the code when they are approved by the local Building Official. The Building Official will typically approve an alternate provided there is some authoritative back up. This would be an Evaluation Report, a manufacturer’s directive or possibly a paper from the SMA.

SMA AND AUSTRALIA

The SMA has been in contact with the Australian government. Currently we are merely exchanging ideas and learning from each other on best practices. The representative for the Australian plastering training programs is coming to the U.S. next year and will meet the SMA executive director to further explore opportunities for each side. Do you speak Aussie?

1. Rendering is the Australian term Americans use for:

A. Decorative paint over cement stucco

B. Cementitious stucco

C. An acrylic finish coat

D. Stucco over masonry

2. The most common form of stucco in Australia is:

A. Lath, scratch, brown and color

B. Stucco over foam

C. Acrylic finish over cement board

D. Venetian plaster

3. In Australia when a construction worker asks for a top hat, what does he want?

A. Furring channel

B. A lid for a bucket

C. A toilet

D. Your hoodie

4. Sarking in Australia is what in America?

A. A short shark hunting trip

B. A water and air barrier

C. A prime coat of paint

D. The double-back method of plastering

ANSWERS … 1.D, 2.C, 3.A, 4.B

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

SMA’S 4TH ANNUAL GOLF TOURNAMENT – SEPTEMBER 22

The 4th annual SMA golf tournament is set for September 22 at Strawberry Farms in Irvine, CA. The format is a scramble and the course is challenging. This is a great place to network with industry friends and have some fun. <<SIGN UP NOW>> We would like to thank our Major Sponsors that make this tournament a success. The SMA encourages you to support these companies as they have supported the industry and promotion of stucco.

SMA acknowledges these outstanding companies and their fine products:

OMEGA PRODUCTS

Omega produces a wide range of quality stucco products.

FRY REGLET

Fry Reglet is the premier name in architectural trims for drywall and plaster.

CAL PORTLAND CEMENT

Cal Portland (Riverside) cement has been a Southern California leader in plastering for decades.

PAREX USA

Parex is a global company with possibly the largest range of products in the industry.

TREE ISLAND STEEL

We know them as K-Lath, a long history of unmatched quality for lath and trims.

MEMBER MEETING IS AT NEW LOCATION: SEPTEMBER 21

The SMA’s September 21 membership meeting will be at a new location — The Club at Anaheim Hills. We plan a great lunch and plenty of parking. <<SIGN UP NOW>>

The topic will be sand. Sand makes up over 70% of any stucco mix and we have had issues with supply and quality; what the future holds is very uncertain. Todd Miller of ACG Aggregates is an expert at sand, sand sources and what future supplies look like. A small panel of experts will include Tim McGuire and Jim Dean of PW Gillibrand Co. for a question and answer period. Contractors and dealers should attend this meeting and bring their questions on sand. This information will help guide you to make smarter business decisions on your sand selections for base and finish coats of stucco.

AIA AND THE SMA

The acronym AIA stands for American Institute of Architects. Your SMA has an online program meant to introduce architects to stucco basics. This program has been up and running for a few years and the response from the design community has been strong. Architects that log on are not all from the southwest, in fact most are from areas where stucco is not overly popular. Does this mean these areas want stucco? The SMA is here to help them get it.

The acronym AIA stands for American Institute of Architects. Your SMA has an online program meant to introduce architects to stucco basics. This program has been up and running for a few years and the response from the design community has been strong. Architects that log on are not all from the southwest, in fact most are from areas where stucco is not overly popular. Does this mean these areas want stucco? The SMA is here to help them get it.

FEATURE ARTICLES

PROPERTIES OF STUCCO

Stucco, a cladding, is similar to wood, vinyl or fiber cement. Yet, cement stucco seems to be in class of its own. The SMA is often asked what should the compressive strength of installed stucco be? Do the designers ask that of wood or vinyl? The SMA has no official position or set minimum requirement. It should be noted that neither does the building code or ASTM. This makes sense as stucco is not a structural component, it is only a cladding. Some experts claim a standard should be set for stucco. Will this be the standard for all claddings?

It is unlikely most other claddings could meet compressive qualities of a properly mixed and applied cement stucco. Since every siding material serves as a cladding to protect against weather, water resistance and be durable, there should be some guidelines. It is generally agreed that stucco performs well between 1,300 and 3,000 psi.

It is unlikely most other claddings could meet compressive qualities of a properly mixed and applied cement stucco. Since every siding material serves as a cladding to protect against weather, water resistance and be durable, there should be some guidelines. It is generally agreed that stucco performs well between 1,300 and 3,000 psi.

The confusion may come from the ASTM standards that require a manufacturer to produce cements that meet or exceed certain values, such as compression. ASTM C 150 has very high compressive values, around 2,400 psi. This is simple cement with no plasticizers. This product would not be suitable for plastering. A better reference is ASTM C 1328, Plastic Cement specifically designed for stucco work. This ASTM has a requirement of 1,300 psi and tops out at 2,900 psi.

The confusion may come from the ASTM standards that require a manufacturer to produce cements that meet or exceed certain values, such as compression. ASTM C 150 has very high compressive values, around 2,400 psi. This is simple cement with no plasticizers. This product would not be suitable for plastering. A better reference is ASTM C 1328, Plastic Cement specifically designed for stucco work. This ASTM has a requirement of 1,300 psi and tops out at 2,900 psi.

Stucco is essentially fabricated on site with bagged cement products. The conditions for installation can vary widely and rarely match the laboratory. This can result in an even wider range of compressive values for installed stucco. The target to shoot for is about 1,500 psi, a little lower or higher is not a problem.

Excessively hard stucco is often desired by designers, but their is no proof extremely high compressive values provide longer service life or benefit to a cement stucco membrane.

LABOR SHORTAGE AND STUCCO PRICES

The United States is suffering a current labor shortage in the construction trades. The more skilled the trade, the greater the shortage. This puts lathing and plastering as one of the more critical industries likely to suffer during labor shortages in the future. The long-term impacts of a labor shortage can impact stucco market share. The economy works on supply and demand: the greater the demand, supply must follow to meet demand. If demand decreases, supply of workers will naturally decline. A region where plastering prices suddenly skyrocket can be signs of trouble on the horizon. If the cause of high prices is the result of greater demand for stucco, supply should follow and prices will level out. However, if prices climb due to other reasons, such as a lack of skilled workers, this could be problematic. Taking advantage of a crisis for immediate gains can lead to a long-term loss. Designers will move away from stucco to other claddings. This can be noted in regions where stucco once had respectable market share but new trends tend to be moving away from stucco.

Conversely, the opposite is true. If developers have an abundance of labor for a particular trade, extreme pressures on pricing tends to push prices very low and the industry equally suffers. Extreme pressure on pricing results in paying people less, buying the lowest cost products, some not meeting industry standards or ASTM specifications. An example would be sand quality. Well graded and washed plaster sand can cost twice as much as dirty clay-filled sand. Since sand is 70% of the stucco makeup, sand prices impact final costs. Industries that resort to shaving pennies result in contractors losing work, and then consider using inferior quality sand to remain competitive.

Labor for installing lath and plaster requires knowledge and skill. Knowledge to do it right and skill to be productive. Extreme low prices due to pressures on pricing or unscrupulous business practices can reach and impact the labor market. Knowledgeable labor with the skills to perform at productive levels can also be forced to either look the other way at defective substrates and improper flashings or hire lower-cost labor to complete the installations. Regardless of how the super low prices are achieved, the result is the same. Leaks, cracks and marketshare loss.

Labor for installing lath and plaster requires knowledge and skill. Knowledge to do it right and skill to be productive. Extreme low prices due to pressures on pricing or unscrupulous business practices can reach and impact the labor market. Knowledgeable labor with the skills to perform at productive levels can also be forced to either look the other way at defective substrates and improper flashings or hire lower-cost labor to complete the installations. Regardless of how the super low prices are achieved, the result is the same. Leaks, cracks and marketshare loss.

The price for installed stucco can vary around the country. There is no single answer for what stucco should cost to have installed. Regions vary — strong stucco markets tend to use a square yard pricing, while other regions use a square foot price. Price will depend largely on the available labor to install at productive levels. If the production level to install stucco drops and prices also drop, this is a warning sign that material cheating could be occurring. Our installation practices have been altered to allow extreme low wages or unit pricing to deviate from acceptable practices. In either case, market share will ultimately suffer due to poor quality and defects. If prices increase and production decreases, this can be sign of either over complexity in stucco assemblies or lack of a skilled labor pool. In either case, prices hit a tipping points, and market share is lost.

The price for installed stucco can vary around the country. There is no single answer for what stucco should cost to have installed. Regions vary — strong stucco markets tend to use a square yard pricing, while other regions use a square foot price. Price will depend largely on the available labor to install at productive levels. If the production level to install stucco drops and prices also drop, this is a warning sign that material cheating could be occurring. Our installation practices have been altered to allow extreme low wages or unit pricing to deviate from acceptable practices. In either case, market share will ultimately suffer due to poor quality and defects. If prices increase and production decreases, this can be sign of either over complexity in stucco assemblies or lack of a skilled labor pool. In either case, prices hit a tipping points, and market share is lost.

The stucco industry needs skilled workers in lathing and plastering to keep quality intact, production levels reasonably high and installations serviceable to the building owner. It is hard to find any other trade more impacted by skilled labor, or a lack of it. Stucco is and should be a premium cladding, but price tipping points exist and we should know the competition. Often we focus on the fellow plastering contractor when the real competition is other claddings.