Frequently Asked Questions About Stucco Applications

What stucco system is that?

There are three different stucco systems in common use:

- Exterior Insulating Finish Systems or EIFS

- Portland cement based three-coat or conventional stucco systems

- Portland cement based one-coat stucco systems

What is EIFS?

EIFS was developed in Germany and excellent at insulating masonry walls. EIFS is a foam attached to a substrate with a lamina, consisting of a fiberglass mesh encased in a polymer-enriched cement, being applied to the foam. An acrylic finish coat is applied for final decoration. The system has a thin, strong and flexible coating over foam that resembles stucco.

What is a conventional stucco system?

Conventional – or three-coat – stucco will have a mechanically fastened weather barrier, or sprayed or rolled-on air and moisture barriers. Over the weather barrier will be expanded or woven wire lath, and then a portland cement scratch and brown coat. The finish can be a variety of products used individually – or in combination – to provide color and texture to the surface.

What is a one-coat system?

One-coat stucco is a proprietary blend of cements and fibers. It is typically applied over a rigid foam board and lath to provide an Energy Code required Continuous Insulated durable cladding. One-coat stucco is Building Code compliant, tested and proven since the 1970s.

Is a one-coat system really one coat?

No, one-coat refers to the fact that the conventional basecoat that is applied in two coats (scratch & brown) to a nominal 3/4 inch thickness, can be applied in one coat to a nominal 1/2 inch thickness over foam or other rigid sheathings. All other items, building paper, trims and the finish coat are the essentially the same as a conventional stucco.

Do the building codes apply to these systems?

First there are broad national specifications to consider. EIFS and conventional stucco applications are part of the International Building Code (IBC). One-coat stucco systems have a third-party report from a model code agency as an application guideline. Manufacturers’ reports can be found on their websites or on the ICC website at www.icc-es.org.

What are hard coat stucco systems?

These are terms associated with one-coat and three-coat stucco systems They are described as hard coat systems because the base coats used for these wall assemblies are formulated with portland cement as the ‘backbone’ of the assembly.

What are water barrier systems?

The strategy behind water barrier systems is to never let any water past the cladding. In other words, when built right, the water never penetrates past the outer surface of the wall to the inner cavity where the moisture can affect the insulation and drywall. This is difficult but possible to do; however, once there is a failure, it can easily become catastrophic because large volumes of water can be trapped for an extended time before someone knows it: That can result in rot, mold, and expensive repairs.

What are water management systems?

Water management systems make the assumption that water will eventually work its way past the outer surface of the wall. But when it does, a system of flashings, weather barriers, and metal or plastic screeds will direct water back to the outside of the structure. All portland cement/hard coat systems – either one coat or three coat – are based on the ‘water management’ strategy. The SMA has additional information on stucco systems at:

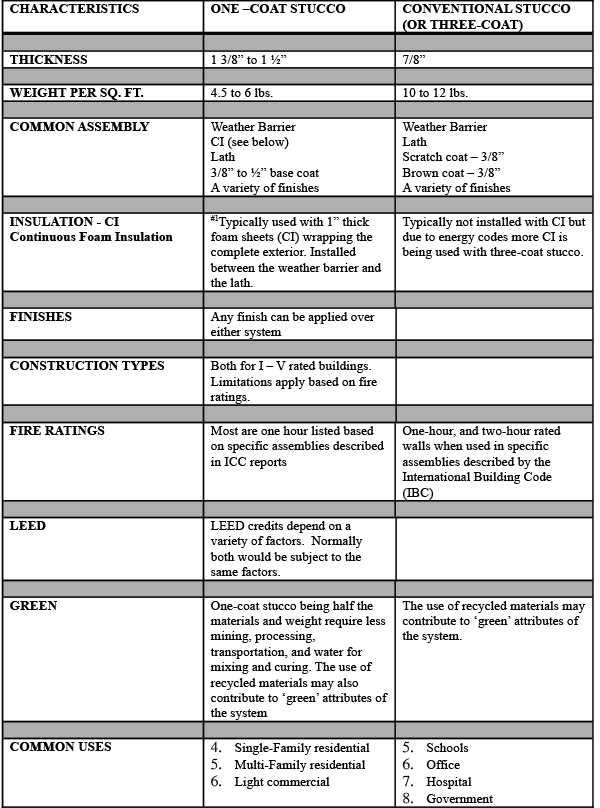

One-coat systems and three-coat systems

What components get blended together to make stucco?

- portland cement,

- lime,

- fibers,

- additives,

- and aggregates – usually around 70% of the mix

What is the role of aggregates in a hard coat stucco system?

Aggregates – also called plaster sand when used for stucco – give cement plaster the body to be able to work in three dimensions. When the aggregates are graded and proportioned correctly – and combined with portland cement – the matrix cures into a hard and durable wall. Properly graded and proportioned aggregates save you money, because they provide the maximum yield for a stucco base coat.

How does a contractor get aggregates for the base coat?

The applicator has sand piles delivered to the jobsite along with pallets of cement. They can blend together in a mixer.

Are there issues with sand?

The biggest issue regarding sand in stucco is the availability of quality sand for cement plastering. Since sand makes up to 70% of the mix, the sand is more important than most people think. Sand must be clean (washed), proper gradation and angular to provide good plaster. Sand used in field mixing plaster must comply with ASTM C 897 and be free of deleterious materials.

What’s the alternative to a jobsite sand pile?

The answer is an ‘Engineered Mix.’ An engineered mix is a stucco base coat preblended at the factory, with cement, additives, fibers, and DRY graded & proportioned plaster sand. Every bag – every batch, every day – is designed to maximize the base coat’s yield, strength and long-term durability.

When can you apply stucco products?

There is a temperature range for the application of portland cement stucco base coats and finishes:

- Ranges are generally between 40°F and 100°F.

- Conditions such as rain or the onset of freezing conditions within a certain time after application also matter.

- Check the manufacturers’ instructions!

What else can I do to improve the quality of stucco?

There are three things that make a big difference in the outcome of a stucco project.

- Using an engineered mix

- Hard-floating the stucco base coat

- Proper water curing of the base coat

What about colored stucco or exterior stucco – how is it applied?

Colored stucco or exterior stucco is a cement/lime mix that is highly durable and cost efficient product for adding texture and color over one-coat or conventional stucco systems. The manufacturer’s offerings on colored stucco usually include a selection of aggregates for achieving various textures. The skill of the applicator also comes into play with textures for colored stucco.

The most important consideration when using colored stucco is the selection of the color. Colored stucco does not have the color range of paints and acrylic finishes, nor is it monolithic in appearance. Unlike paints or coatings for hard coat systems, colored stucco provides a surface with porosity and depth that allows texture, color, and light to interact. Colored stucco could be described as a living finish that changes with light and time. The SMA website provides additional information on colored stucco at:

ALWAYS LOOK AT A SAMPLE OF THE TEXTURE AND COLOR FIRST – BEFORE MAKING A FINAL DECISION!

Can you paint stucco?

Yes, painting stucco is a very common application but paint doesn’t provide a ‘texture’ for the wall. Most stucco manufacturers offer an exterior stucco product that’s gray in color and blended without pigment. This product is used to add a design or texture to the wall and then the wall is painted. Just like colored stucco described above, the aggregates and the skill of the applicator are important considerations.

What paint can I use for stucco?

All cement plaster, no matter what the system, has a high pH content that can be detrimental to paints. New stucco (within the first year of application) should be primed and painted with the paint manufacturers’ coatings designed for high pH surfaces. It is important to follow the manufacturers’ instructions for 1) the type of coating to apply, 2) the timing between coats, and 3) the finished mil thicknesses when the coatings are dry. The information you need to make sure the right paint is applied correctly will be found on the paint manufacturers’ website.

What kinds of problems are the most common with stucco systems?

Complaints about the finished color, cracks, and efflorescence are the most common issues applicators and manufacturers may be called out to observe.

Color

Complaints about color are generally because the applicator and the owner did not properly discuss the finish and do a large enough sample before the project was completed. It’s very important to educate owners before the finish is applied regarding expectations on colored stucco how these finishes differ from paints and coatings.

Cracks

The SMA receives a lot of questions on this topic, but without first-hand observation it is very difficult to provide good answers on any particular outcome. Some cracking is to be expected and can be commonly seen radiating from the corners of windows and doors. What is out of the norm or deviates from industry standards is a subjective and difficult assessment. The best policy is to be proactive before the project starts and aggressively design stucco systems resistant to cracks. The engineered mix described above is an important tool to consider. In addition, stucco manufacturers offer crack resistant systems that are very effective at limiting cracks. The link below provides more information on crack limiting systems:

Wood-based sheathing issues due to rain

Wood-based sheathing exposed to rain can swell, buckle and create an uneven substrate for cement plaster. This condition can result in an uneven cement membrane which in turn may result in more cracking. The thinner areas of cement plaster will be more susceptible to stress cracking. It is recommended to install wood-based sheathing with small gaps to allow for expansion and keep dry as possible.

What procedures should be followed to go over existing brick with stucco?

- Conduct a visual inspection to check for loose brick and then check the condition of the surface.

- Make repairs as needed and thoroughly clean the brick.

- Use a high quality surface bonder similar to Weld Crete by Larsen’s products. Follow the bonder manufacturer’s instructions for application and when to apply cement plaster over the bonded surface.

- Follow the guidelines of ASTM 926 Table 4 for two- or three-coat application of cement plaster.