MESSAGE FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

2018 was a big year for the SMA, and 2019 promises to be even bigger. We finalized our Silica Compliance Program and signed up contractors from all over the United States. The SMA provided many with Competent Person training and cards to verify training and even made training available online to members. We have continued to test and improve our engineering controls to better protect workers and ensure employers are in compliance. The SMA has also worked closely with OSHA and CALOSHA on the written exposure plan. We have provided SMA test data from air monitoring with both agencies as industry Objective Data. We will continue to work with OSHA to better protect our most valuable asset, your workers.

The SMA Board of Directors has always been thought of as a California group. Today, though, we have directors from all corners of the United States serving on the SMA board. This makes the SMA more well rounded and a better voice for the state of the stucco industry across the entire United States.

Apprenticeship is a concern for all contractors, and even more so for the skill-intensive trades. Lathing and plaster would certainly qualify as skill intensive. The Department of Labor recognizes that this industry is hurting with regard to training. However, they noted the industry is too segmented or regionalized to select one or the other group to expend efforts with. The SMA has made great strides in unifying the states and it has not gone unnoticed by the Department of Labor. Their 2018 funding for education went to other groups as the SMA was not and is still not quite there to stake a legitimate claim for funding to train lathers and plasterers. However, recent efforts by board members in Texas and Florida have helped gain the attention of Washington D.C. Hopefully in 2019, we can secure a formal training program with some form of certification to designers and building owners.

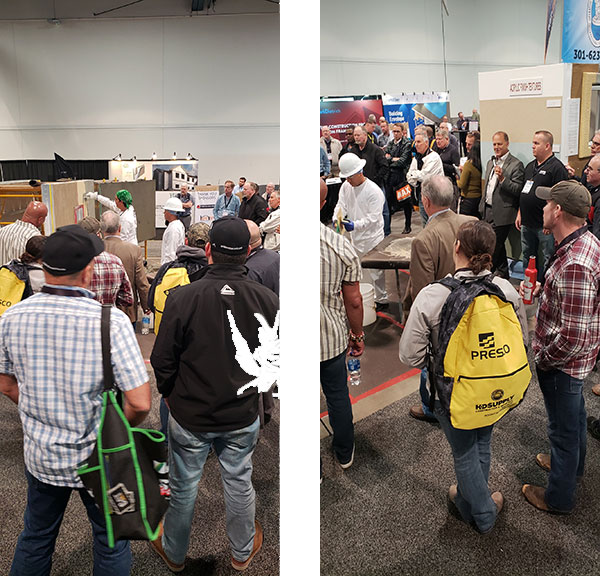

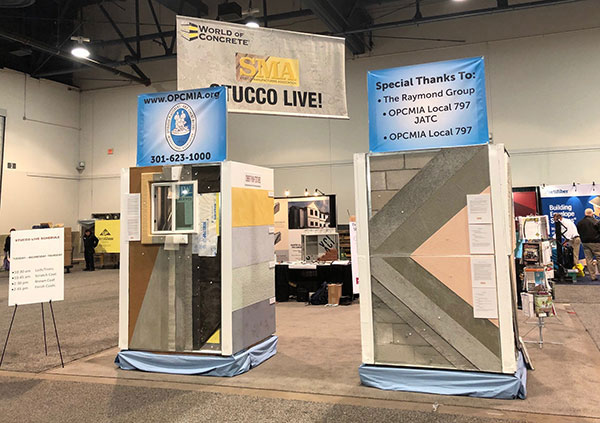

STUCCO LIVE 2019: Recap from the World of Concrete, Las Vegas

The SMA hosted the STUCCO LIVE event at the World of Concrete show that was held in January at the Las Vegas Convention Center. For four days the SMA booth and STUCCO LIVE stage area was very busy. Crowds intensified during the live presentations of lath and applications of plastering. The Operative Plasterers and Cement Masons Associations (OPCMIA) was instrumental in making the show a huge success. The popularity of the live exhibits was proof that stucco is desired and market share for stucco has room to grow. We need to keep stucco promotion going.

Thanks also go out to our SMA member sponsors. Their contributions were not just a financial help – we had many SMA members working the floor of STUCCO LIVE. They provided expert advice to attendees with questions on water-resistive barriers, lath, cement and acrylic plasters.

Thank you SMA members and sponsors:

INDUSTRY UPDATE

The stucco industry is estimated to be a $2 billion a year industry per the US Census Bureau. This can change: the cement stucco market can grow, or it can shrink. This depends largely on the actions of us as a united industry. Make no mistake that other claddings want more market share, and they have instituted strategic plans to grab stucco market share. One major cladding has gone as far as offering free inspections for stucco buildings that result in recommended removal and replacement with their products. All industries need to be guided. While fighting for your company’s share of the market is understandable and needed, so too is a collective plan to grow overall market share. After all, a greater percentage of a shrinking market is still a shrinking number.

The good news is that cement stucco is one of the best claddings on the market. The US Department of Energy has recently released a report on the life costing and life span for cement plaster on buildings and news is very good. But only a concerted effort and strategically supported marketing plan can ensure the word gets out to the public. There is much work to be done and resources are needed to ensure our market does not vanish.

The masonry industry suffered substantial loses in market share a few decades ago, but they then invested in the industry, developed a long-term plan that included industry promotion, education, free technical services to the design community and litigation support. That investment has yielded results. The stucco industry should take a similar path.

ASTM STANDARDS

ASTM standards are constantly changing. ASTM conducts two committee weeks each year, filled with meetings to discuss changes. In addition to these semiannual meetings, most committees have conference calls monthly to discuss revisions to standards.

The process is not simple by any means. Proposed revisions are discussed during work group meetings, sent out to ballot, and voted on by voting members. If it passes the ballot, it is sent to a higher committee that may approve or reject it. If it is approved, it is written into the standard the next year.

I attended Committee Week in November of 2018 and I was surprised with what I experienced. There were some manufacturers, but not as many as to be expected. There were even fewer contractors. The majority of those present were engineers, architects, and third-party inspectors. These inspectors earn a living in most cases by offering observations and litigation support, many times on the side of the plaintiff. Not all of them are bad, and I felt a few of them have good intentions for our industry. Others clearly have an agenda to keep certain parts of the standard intact, so they have a way to make a decent application appear to be insufficient. This is how they make their money, and cause problems for our manufacturers, contractors, and industry.

These are not the people who should be making the rules regarding how our work is done. Many of them have never held a tool. They simply know how to work the system, find a small error in an application, and make the contractor pay to fix it; regardless of the actual cause, related or not.

It costs $75 and a little bit of time each year to join ASTM and become a voting member. You also receive a copy of the standards book for the year. This is cheaper than buying just one standard online. I encourage everyone involved in our industry to join and participate. The only way to keep up with the standards and have a say in changes made is to join and vote. If you do decide to join, ask to be added to the C11 Committee and any other committees that pertain to work you perform. C11 also has a stucco work group that meets every month to discuss revisions. It would show we care about our livelihood if we had more participation from contractors and manufacturers. If you have any questions or need assistance joining any of these groups, please contact me directly.

Rick Durham, General Manager – EZ Wall Concentrate

214.859.2120 – rdurham@ezconcentrate.com

SMA MEMBERSHIP MEETING

On February 27th, the SMA member meeting will cover the “State of the Industry.” This is more relevant than ever before as news from one corner of the country travels fast and impacts all regions. In addition, the SMA board of directors now has the widest reach across our nation like never before. Join us to learn what is in store, trends that are happening under our nose and then work with us as a team to secure the future of stucco. Sign up today.

SAVE THESE DATES

Mark your calendars now to SAVE THE DATE for upcoming SMA events:

- May 22: Membership Meeting

- September 23: Annual Golf Tournament

- November 6: Membership Meeting

Feature Articles

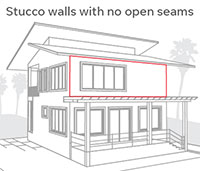

THE NAIL-FLANGE WINDOW

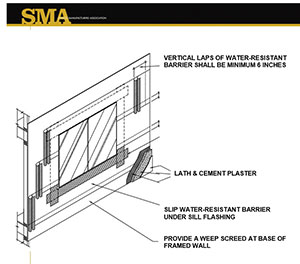

This type of window is well suited for cement stucco. The nailing flange is used to support and attach the window. A proper flange can also allow for flashing strips to be installed and integrated with the water-resistant barrier to shed incidental water down and out. This is compatible with the concealed barrier or rain screen moisture management options employed on stucco over framing wall assemblies. The SMA has published a guide for recommended procedures for flashing a nail-flange style window when used on framed walls that will receive cement plaster (stucco). While using a casing bead and sealant is never a bad idea, some prefer to abut the stucco directly to the window. This lowers maintenance issues and is often considered more aesthetically appealing. The SMA supports this practice with caveats. The full document explaining the SMA position is on the SMA website under Technical Resources.

Plastering contractors are advised to download the 4-page document, review the “performance” data and ask the developers if their project, windows and specifications allow for abutting stucco to the window frame. Only the SMA publishes a document that clearly allows this practice to be done. Contractors should be aware that not all projects, windows or regions of the country will meet the caveats. It is not your responsibility to design or select windows. The developer or designer of record should have all that information readily available. This procedure is simply to ensure they did their job, so you can do yours. Following this protocol will help eliminate leaks and protect you from litigation claims.

PAINTING STUCCO?

This is a question frequently asked by building owners. They rely on the SMA for an unbiased opinion. SMA members should know what we are saying. This article will try to cover many of the concerns and questions the SMA gets on painting or re-decorating cement stucco.

GENERAL: Cement stucco does not need to be painted. However, it can be painted if desired. In some parts on the country contractors use paint to seal cement stucco. If the cement is properly mixed and applied, it will be resistant to the passage of moisture. Good application of cement plaster requires the cement to be densified to consolidate the membrane. However, painting stucco does not have a negative impact on the cement. It is recommended to use paints made for cement that are alkali resistant. Acrylic finish stucco is not a cement product and using a good acrylic paint will allow a cost-effective color change. The following is for cement stucco finish.

Cracks: Hairline cracking is inherent in cement stucco and rarely a source of leaks. Generally patching narrow or tight cracks is not recommended. The patch can look worse than the hairline crack. Even after painting. Cracks that are larger and a concern should be investigated and patched by professionals. Elastomeric coatings can hide cracks [see Vapor Permeability].

Vapor Permeability: A cement plaster or stucco cladding was intended to breathe. This means to allow moisture as a vapor to pass through the cement. It therefore makes sense that the paint or coating should be vapor permeable, too. Acrylic paints are the most often used and they are vapor permeable. Elastomeric coatings go on thicker and have the ability to stretch. This makes them excellent at covering and hiding cracks. One concern is the lack of vapor permeability for elastomeric coatings. They keep water out, but they can also keep water in. Over time, vapor drive can push the coating and form bubbles or blisters. Before using an elastomeric coating on stucco, talk to local dealers and contractors to verify successes or failures in your region of the country.

Fog Coating: This is a cementitious paint made by stucco manufacturers to blend or even colors on integrally colored finish cement stucco. Generally not recommended to use for a color change. The product is dry cement, lime and pigments that are mixed with water. Application is done with a hand-held garden type sprayer. This is not a do-it-yourself operation – ask your plastering contractor for help.

PH level: Fresh cement will be high in alkalinity. It is common for cement stucco to be around 12 to 13 on a Ph level. The good news is that level tends to drop in the first few weeks. Painting fresh stucco should be held off until the Ph level is below 8.

Water Resistance: Integrally colored cement stucco finish will darken when wet. The color will return when the stucco dries out. Painted stucco has the advantage of not getting dark when wet. Acrylic finishes will act like painted cement stucco.

Color Selections: It should be noted that salts are always present in cement products. They can leech out when the sun heats up the wall to draw out the water that may contain salts. This is called efflorescence. Darker colors tend to not only show more efflorescence, they can allow the wall to heat up more and faster, making efflorescence appear more often.

Painting a Sand “FLOAT” Finish: This has been recent issue on many projects as designers want to return to natural cements and then paint the new stucco for color enhancement. What can happen is the owner will run their hand along the wall and note the cement plaster will appear to flake off. They become convinced the contractor did something wrong as the house next door that is 15 years old does not have this issue. Here is what is happening:

To obtain the float finish, the plasterer floats the wall with a wet sponge-type float. This is to bring the sand to the surface, making it look like a uniform sandpaper. This means that some grains of sand are only semi-buried in the cement paste. It can be particularly noticeable with more angular sands. Picture a triangle shaped grain of sand with only about 25% of the tip in the cement paste. The painter comes along and sprays the wall with paint. A few days later the owner touches the wall and those tiny grains that were just hanging on, break off. See picture.

In reality, the cement nor the paint coating is fully cured. Over time, they will both cure and become much more resistant to sand breaking off. This is not new but more of an issue as designers are moving away from larger sand (16/20) to more fine sand (20/30). The finer sand has more grains at the surface and therefore more exposure to the problem.

TIPS: If painting a new sand finish is to be done, a very soft brush can be run over the stucco prior to painting. This will help remove very loose sand. A painter can also back-roll after spraying to help dislodge loose particles. Even after this, it can and will occur. It is recommended to touch up the areas just prior to turning the building over and ask owners to be a little careful for a few months. Once the cement and paint both fully cure, this issue generally goes away.

Acrylic versus Cement Finish: Both are great products to use as final decoration on cement plaster. Acrylics tend to be much better on color and texture uniformity. They tend to require a better brown coat and primers are recommended. Colors can be a very wide range. Owners can pick from any paint color chart and your stucco manufacturer will match it. Most texture with acrylic finishes are sand or float finish as this is not their strong suit. They also do not have the sand issue flaking off issue that is more common with painting new cement stucco.

Cement finish stucco is lower cost and offers the widest range of textures. Even smooth trowel is done more with cement as the troweling action brings up what plasterers call “fat” to fill minor imperfections. Cement finish tends to show more hairline cracks. Very dark colors in cement are not generally advised with integrally colored cement finish stucco.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.