FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

2022 SMA Board of Directors

The last few years have been tough, the SMA postponed board elections, stopped in-person meetings and canceled the annual golf tournament. The SMA is about to re-launch in-person meetings and working to making them virtual so out of state members can join in remotely. The SMA Board of Directors are from all over the United States: your current SMA Board is:

Dale Nehls, President, Quikrete

Kevin Wensel, Vice President, Omega Products

Tom Susko, Treasurer, Home Plaster Inc

Herman Guevara, Plastic Components

Dennis Deppner, Master Wall, Inc.

Gary Goodwin, K-Lath

Kevin Ordiales, Ashgrove Cement

DJ Farley, Weatherization Partners

Chip Blome, L&W Supply

The SMA board meets quarterly to discuss the industry and provide guidance to projects and direction taken by the SMA. This includes past accomplishments such as the only Silica exposure plan dedicated to plastering and adhered stone work with “Industry Objective “data on Action Levels and PEL. The six modules of on-line training for lath and plaster, including a supervisor’s class for plastering. The Stucco Market Study that uses US Census bureau data and ties it directly to the plastering industry. Tech Times Bulletins on recognized industry practices for lathing and plastering.

SMA HAPPENINGS NOW: The SMA routinely works with a variety of entities in the stucco industry and on occasion we get out to live events. The SMA recently was in Denver at Smalley and Co to do a training class on SMA Modules and certification. The even was well attended by local stucco contractors.

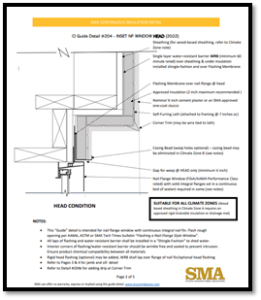

SMA UPCOMING: The SMA is working on a series of stucco details and a design guide. With three live webinars completed for Architects, the SMA has now become the leading source of information regarding lath and plaster product selection and design concerns. The request for details on stucco regarding Continuous Insulation, Rain Screen, over CMU and if the water-resistive barrier can be placed over the plastic insulation is immense. The SMA is responding with the largest library of details known in the industry. This includes tips, caveats and recommendations regarding Climate Zone. For example, Continuous Insulation Stucco for an Inset window (see graphic) is 6 pages covering an overview, head, jamb, sill, drip edge and options for stucco abutting the window frame. Details are reviewed by experts in building science, architecture and defect litigation. They are generic and considered “Guide” details to help designers create their own details that lath & plastering contractors will find constructable and cost effective.

CONTRACTOR ALERT

SMA Contractors – the new Silica Exposure Plan is available. All contractors are required by OSHA to have a Plan, perform air monitoring and have the Plan reviewed annually. The SMA does the air testing for various tasks (specific to lath/plastering and adhered masonry). You should print the plan and have that current plan available to workers, this can be inserted into your safety binder. The other requirement is to have an assigned Competent Person. The SMA provides a free on-line class for your Competent Person. There is a 25-question test to verify comprehension. A pictureID card can be issued upon passing the class upon request. There is also a tool box talk sheet that foreman can use to ensure you cover what OSHA requires be taught to your workers. The tool box form is also available in Spanish. Contact Marlene@Stuccomfgassoc.com

ASTM C1063

The SMA is frequently asked about ASTM changes to keep up to date with regard to installing lath and plaster. ASTM C 1063 is a nationally recognized standard used for the installation of lath for Portland cement plaster. It is a living standard that changes and evolves through committee action. Historically, the standard change very little. However, recently those changes have been more often and impactful.

The SMA is an organizational member of ASTM and compared the 2006 version to the 2020 version of C1063. The standards bare little resemblance to each other. The most notable changes are below. The next SMA newsletter will cover changes on C 926 (the application of cement plaster).

Most changes are related to shifting sections and edits or grammatical changes. Often new references need to be added to connect to related ASTMS. The SMA includes the section number for reference and a brief recap of the new language. SMA commentary is added if an explanation or caveat is advised.

The SMA provides this as a service to members, for exact language refer to ASTM C 1063-20.

2020 ASTM C1063-20

SUSPENDED CEILINGS: The older ASTM version had a large section on the rules for design and installation suspended cold rolled channels with various tables related to lath and plaster suspended ceilings. That language was removed and made as an ANNEX. It is still mandatory ASTM Language.

CONTROL/EXPANSION JOINTS: The most notable change related to these joints is adding a definition for each.

Section 3.2.2 now defines a control joint as a joint that accommodates movement of plaster shrinkage and curing along predetermined, usually straight lines.

Section 3.2.3 Expansion joints are defined as a joint that accommodates movement beyond plaster shrinkage and curing. There is now a NOTE or reference to design considerations shall see ASTM C926 A2.3.1.2. This C926 section states both control and expansion joints, including the integration with the water-resistive barrier shall be graphically depicted in the contract documents.

SMA Commentary: the SMA feels the new definition helps provide some guidance. In addition, adding the requirement to “graphically” depict joints on drawings (contract documents) will help contractors. The SMA agrees it is the architect who should decide where and how many control joints are needed. Including not requiring any control joints as they have the right per ASTM under “as specified” provisions. This is important as adding control joints after the plans have been approved by the city should be considered a legitimate change order item and not a design error by the designer or hidden cost assigned to the contractor. The SMA can help with this issue.

DELIVERY/STORAGE

Section 4.2.3 lath with factory paper backing shall be stored and handled to prevent puncturing the paper.

SMA Commentary: It has been reported that paper backing can be damaged during the delivery process. Suspicions are the paper-backed lath sheets may have vibrated resulting in damage to the WRB.

DESIGN/PRE-INSTALLATION:

Section 6.1.1 framing member deflection shall not exceed L/360

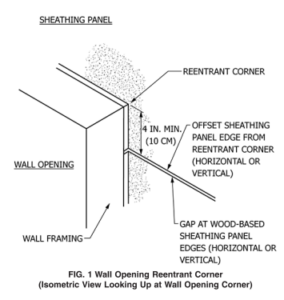

Section 6.1.4 wood-based sheathing edges shall be offset a minimum of 4 inches from wall openings (see Fig 1) .

SMA Commentary: Many installers felt this was great news, the problem is if the stucco is removed and the joint is within 4 inches of the reentrant corner, you may be deemed in nonconformance to ASTM. Walk your project and at least notify the general contractor it may be an issue. Document that you pointed it out, particularly if they refuse to fix it.

Section 6.1.5 wood framing shall have a moisture content not to exceed 19% immediately before plastering

Section 7.2.4: damage to the WRB shall be made with the same or an alternative material compatible with the water resistive barrier before plastering.

Section 7.2.5: Z furring is now considered a customized furring system and shall be engineered.

TABLE 1– Flat rib lath is no longer permitted on unsheathed walls – Hi-rib is no longer permitted on all walls.

New ASTM – Refer to ASTM C 1861 for instructions on trim accessories

Section 7.3.2.4 Except for weep screeds, designated drainage screeds with solid flanges, the water-resistive barrier shall lap the flange of the accessory.

SMA Commentary: Short Flange casing has been used for several decades with no issues. The SMA agrees that “expanded” flange casing should not be covered, but short-flange casing, reveals and other may be covered, it is more of a design and intent issues. The SMA will stand with “alternates” on a case-by-case basis.

Section 7.3.5.2 Lath to concrete or masonry. Attachment is now prescribed as 16-inch OC as if the wall is framing with ¾ inch penetration.

SMA Commentary: The SMA still stands with one fastener per square foot is an acceptable practice.

SMA writes letters on a daily basis covering a variety of issues. Including code interpretation as well as ASTM interpretation. The SMA has been very successful with building departments when an interpretation on ASTM language is needed. EXAMPLE: Both old and new ASTM C1063 call for discontinuous lath behind a control joint. Continuous lath is routinely done and is a recognized industry practice by the SMA.

JOB PROBLEM OF THE MONTH

The SMA gets calls and emails from all over North America on stucco related concerns and troubles. With modern technology and camera phones, pictures can help make the story come to life. The goal of this new section to make contractors aware of issues and hope to help them avoid these issues themselves. There is no shortage of case files.

In Florida it is common and recognized to apply a lace texture to the brown coat and then paint as the final decoration. This homeowner could not understand why the paint was peeling off the stucco. While it could be considered a paint issue, the paint pulled off the stucco texture with it.

The SMA determined there were two issues

1. The cement texture was watered down to allow for workability, and possibly an additive. This resulted in a weaker than normal cement to cement bond.

2. The paint was applied only a few days later. The high alkalinity of the cement caused what is known as pH or alkalinity burn. This resulted in a breakdown in the binders used in paint. Paint should not be applied until the pH is near neutral (7)

NOTE: No weep screed was used because the plaster is over a solid masonry wall. This is code compliant and unrelated to the paint/stucco failure issue.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.