MESSAGE FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

The new OSHA Silica Exposure standard is here, and soft enforcement has begun. OSHA will be looking, and good faith efforts to comply with the new standards will be required. Being enrolled in the SMA Compliance Program is a good start. The construction industry had a PEL of 250 micrograms per cubic meter of air as an 8 hour-Time Weighted Average (TWA). The new PEL has been reduced to 50. This is a significant reduction, and OSHA states it will save thousands of lives by reducing the fatal illness known as silicosis. For information about the required written exposure plan, competent person and other requirements, refer to the SMA Silica Compliance Program [click here]. The SMA has done industry testing and prepared a plan for plastering and stucco work. There will be more upcoming tests and updated Exposure Control Plan. Being in the SMA program will keep you informed of changes.

ASBESTOS: The plaster industry has raised concerns that this is likely the next ‘asbestos’ issue. While similarities exist, there are also significant differences. Unlike asbestos, silica is one of the most common materials found on earth. Banning silica is not feasible. Unlike asbestos, the OSHA standard known as 1926.1153 sets protocols for compliance, not a ban of the product. Adhering to these work rules will better protect employees and keep employers in compliance. To learn what you need to know, the SMA has a link [click the cover image at right] to the OSHA “Small Entity Compliance Guide.” This guide is the explanation to the ruling, compliance and allowable paths to compliance.

ASBESTOS: The plaster industry has raised concerns that this is likely the next ‘asbestos’ issue. While similarities exist, there are also significant differences. Unlike asbestos, silica is one of the most common materials found on earth. Banning silica is not feasible. Unlike asbestos, the OSHA standard known as 1926.1153 sets protocols for compliance, not a ban of the product. Adhering to these work rules will better protect employees and keep employers in compliance. To learn what you need to know, the SMA has a link [click the cover image at right] to the OSHA “Small Entity Compliance Guide.” This guide is the explanation to the ruling, compliance and allowable paths to compliance.

FALL WEATHER: Fall is here and cold weather is just around the corner. While cooler weather can increase production rates and lessen the need for damp curing of cement plaster, it also can mean workers need to start covering materials and thinking about rain, frost and even snow fall. Shocking to most plasterers in the southwest, cement stucco is done in cold climates and winter protection is an annual concern. Minnesota and Alaska both use stucco with regularity, and stucco has performed well for decades. Russia and Germany rely on stucco to clad most of their buildings. After all, what other cladding material actually gains strength over time?

STUCCO & FIRE: The recent fires in California also point to another major benefit of stucco. The cement membrane is noncombustible and provides superior fire protection for homes. Historical studies have clearly shown cement stucco outperforms other claddings for fire protection, durability, design flexibility and economy.

STUCCO PROMOTION: The SMA is working on a plan for greater promotion of cement stucco. Other claddings with far less qualities than stucco are taking market share. Do not believe that designers do not like plaster or that stucco is not suitable for their projects. It is about promotion. We need to promote to designers and not to ourselves. Other claddings have large budgets and work hard to develop well thought-out and executed marketing campaigns to promote their claddings to architects. It is time for stucco to do the same. We need to develop a marketing plan for stucco. We need to reach out to designers and developers and have them take a second look at stucco. Since stucco is primarily a site blended and generic product, it must be the contractors that help push the need if they want to insure future market share. Market share will not increase without a concerted and purposeful effort. Other industries do this, but plastering promotion to designers has been seriously lacking for decades. The significant increase in stucco contractors signing up to the SMA due to the Silica Exposure Control Plan could provide the funding needed to develop such a plan. The SMA welcomes all the new plastering contractors and hope they join us in the pledge to work on plans to increasing stucco market share.

SMA GOES TO TEXAS!

The SMA will be presenting a stucco class to a group of Texas developers on November 1 in Austin, Texas. The program will be to educate developers on stucco and promote greater use of cement plaster stucco on projects. This is the first SMA program in Texas, and we have others planned in other states. The SMA is the national voice for plastering, and growth of the SMA equals growth for plastering and stucco market share. The in-person presentation complements our on-line AIA classes that are already taken by architects from around the United States. Supporting the SMA supports your business growth in enhanced market share.

SMA GOLF 2017

The 2017 golf tournament was the biggest ever. The private Yorba Linda Country Club was appreciated by the SMA membership, and we will be returning next year. Our raffle was filled with great prizes thanks to our sponsors.

SIGN UP NOW: NEXT SMA MEETING ON NOVEMBER 8

Chris Thornberg is BACK! SMA members have enjoyed Dr. Thornburg’s witty and entertaining presentations on the economy. For those who may not know, Chris predicted the crash of 2008 before most had a clue trouble was on the horizon. What he predicts now about the economy and the housing/building crisis could be helpful to you and your business. The meeting is set for November 8 at the Yorba Linda Country Club. Plan to attend — a sellout is expected. Click here to sign up online now.

Feature Articles

What Is the SMA?

If you are new to the SMA, welcome — and let us tell you about us. The SMA is a national not-for-profit industry trade association formed in 1957 to improve stucco, enhance products and educate the industry. We do this through collaboration of manufacturers, dealers, contractors and industry consultants. We produce technical papers, provide assistance to designers and contractors on all issues related to plastering/stucco. Unlike many other groups, we are not conflicted by supporting other cladding or materials that take work away for the lath and plastering contractor. We also have networking events and — with new contractors signing up from around the United States — it is hopeful we will soon be able to hold regional meetings in other areas of the United States. The SMA has committees to focus on specific issues and improve stucco. Our goal is to educate and help contractors be successful and profitable. We know contracting in lath and plaster is a tough business; we can help. Working together we can make a difference on the future of stucco. Members can use the SMA or L&P logo on business cards, stationary or promotional items. Contact Marlene Lampert at the SMA office for more information.

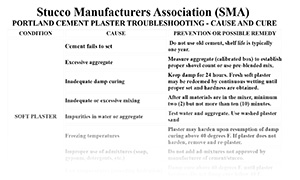

SMA’s Plaster Troubleshooting Guide

Our plaster troubleshooting table was first published in 1965 by the SMA and has been recently updated. The SMA offers this as a general troubleshooting guide of problems or unwanted conditions found or related to portland cement plaster/stucco walls. The chart lists the conditions, possible causes, preventions or possible remedies. Not all of these conditions are in the control of the plastering contractor. This chart [click image at right] can also be used as a pre-installation discussion guide for plaster/stucco projects to help avoid unwanted conditions.

WEEP SCREED, HISTORY AND THE CODE

Building Codes require a weep screed at the base of stucco framed walls along the foundation plate line. The weep screed was introduced into the code in 1970 and, over the years, more clarifications were added.

- Placed at foundation plate line and allow trapped water to drain to the exterior (introduced in 1970 Code)

- To be made from 26 gauge galvanized steel or approved corrosion resistant material (introduced in 1985)

- Have a 3 ½ inch high attachment flange (introduced in 1985)

- The nose is to be 4 inches off of the raw earth ( introduced in 1979)

- The nose is to be 2 inches off of paved services (introduced in 1991)

- The bottom of the weep screed is to be 1 inch below the framing/concrete transition (ASTM 2001)

- The weather- (water-) resistant barrier and lath shall lap the attachment flange (introduced in 1979)

Alternates to code required weep screed are allowed if approved by the Building Official. It is the responsibility of the designer/user to verify the detail is appropriate for the climate and location on the building. The SMA has details providing options, with permission from the local building official prior to usage. Most building departments have accepted the SMA alternates. Contact Mark Fowler at the SMA if you need assistance.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com