MESSAGE FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

I would like to welcome all our new contractor members to the Stucco Manufacturers Association. The SMA Silica Compliance Program has dramatically increased the size of the SMA. This should help the plastering industry. A larger organization means better funding and opportunities to help the plastering industry. The result will be more influence to help designers with the correct selection for exterior siding — which is stucco. Helping the plastering industry helps all of us: whether you are a contractor, supplier or manufacturer, more marketshare means more work for you. An appropriate quote to consider is “a rising tide floats all boats.” For you new members, here is some useful information about the SMA.

Who is the SMA? The Stucco Manufacturers Association was incorporated in 1957 by the various cement stucco manufacturers in the California market. Over the years, the expansion has slowly grown to include the entire United States. The SMA holds quarterly meetings for networking and educational purposes.

Education: The SMA is a not-for-profit educational body and recognized by the design community as the authority on plaster and stucco. Our AIA online class is viewed several times a day by architects from all over the United States. The SMA helps designers with details and specifications on the proper use of cement stucco. The board of directors are keenly aware that some education and training for installers are also needed.

Promotion: I believe education is a form of promotion. If a cladding works because of education and training, it will flourish. Conversely, if a cladding has repeated failures, all the promotional ads in the world cannot help it. We know stucco works, in all climates. The SMA is working on a plan to boost the promotional efforts of stucco in commercial and residential markets. The resources of new members joining the SMA greatly help in that effort.

If you are an SMA member, your livelihood relies on stucco marketshare. Make no mistake — other claddings would love to see stucco lose its hold on the markets where we are strong. The benefits and long track record of stucco make it hard to convince people that stucco is not a good cladding. However, we should not sit by and let chance dictate our future. Stucco has a great future: whether it is three-coat, one-coat, EIFS or cement board systems, there is a system that is right for everyone out there, and we need to work harder and smarter at stucco promotion.

SILICA TRAINING

The first SMA Silica Compliance Training was held and the plaster industry now has 40 card-carrying “Competent Persons” on silica exposure for plastering and adhered masonry. While not every attendee passed the tough written exam, most did very well. The SMA Director was pleased as this was one of the biggest turnouts the SMA had in years. Large and small plastering contractors filled the room, even the OPCMIA made the class. Fowler commented this is important as every employer is required to have a written exposure plan and assign a competent person. This person should be trained at the tasks routinely performed that may put employees at risk of silica exposure. This training will help make workers safer and better the industry as a whole.

The SMA is already scheduled to hold classes in Fresno, Sacramento, Las Vegas, Austin, San Diego and Phoenix. Contact the SMA if you are interested in Silica “Competent Person” training.

Feature Articles

WHY I HATE ONE COAT!

Cement stucco has traditionally been a three-coat system. One-coat is really a two-coat system and merely reduces the basecoat thickness from a 3/4 to 7/8 inch thickness down to a 3/8 to 1/2 inch thickness. One-coat has been around for over forty years and many contractors resist it. The objections are varied from using unfamiliar trims to slight nuances in application. It seems contractors love or hate one-coat.

If you are a contractor who hates one-coat, you may want to ask yourself if you get tired of builders, owners or consultants stepping in to tell you how to lath and plaster when they have no idea about the practice. Three-coat stucco is generic with no manufacturer from start to finish. This opens the world interpretation to any and all. This can be the consultant who has never seen stucco or a homeowner who saw something on television and knows you are getting to them.

This is when a one-coat manufacturer can really help. One-coat is a system, the manufacturer is the king of the system and can be of great help when you need an educated and reasonable clarification to a situation. Consider how many times you have read project specifications that stated to install per manufacturer’s recommendations as opposed to install per contractor’s recommendations. This is a tool many contractors fail to use. Most manufacturers are very adept at how their systems work. They can be a great assistance if you know how to use them. This does not mean trying to get them to cover mistakes or improper workmanship, but does mean they can be flexible to work with you as a partner to insure the owner gets a stucco job that works without spending money on pointless or redundant extras.

Another thought on one-coat is the litigation angle. If you get caught in a case where a lawyer points out that your control joint layout or installation is not per ASTM, you have a hard fight ahead with three-coat stucco. However, with one-coat stucco, you have two quick answers.

- The ASTM covers three-coat, not one-coat, so it is not the correct standard to reference.

- The approval for one-coat is by the code on “alternative materials and methods”; you need to refer to the evaluation report and then the manufacturer for allowable variations to their system.

The other issue that should make you think is the Continuous Insulation craze. One-coat is the only hard coat cement stucco fully code compliant, tested and proven for a cement stucco over a rigid foam. While three-coat cement plaster over rigid foam works, back-up from authoritative sources can be challenging. Not the case with one-coat stucco — it was born over rigid foam sheathing. If you hate one-coat stucco, you may want to re-think it.

TEN THINGS EVERY STUCCO CONTRACTOR NEEDS TO KNOW

-

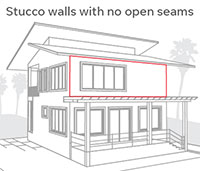

Flashing is critical to ensure stucco will work. Flashing: Flashing is important on all claddings, but more so on cement stucco over framed walls. This is because stucco does a great job keeping bulk water out. Conversely, stucco also holds bulk water in. This means bulk water that gets behind the stucco has only a few options. Some will be absorbed and then diffuse as a vapor to the outside, but this is a slow process and water can flow down and must be directed out. Flashing is more critical for stucco and, when done correctly to minimize water enter and direct water out, stucco is the best cladding you can select. Failing to provide flashing can trap water and cause rot and decay, faster than with other claddings.

- Cracking: Cracking is inevitable with a brittle cement cladding. Hairline cracks are not a point of water entry. Even the Romans knew concrete was great for transporting water. The hairline cracks would virtually self-seal on the inside. This should not be used as an excuse for excessive or large cracks. However, crack free stucco is unrealistic and not required for stucco to work.

- Control Joints: The code and ASTM have requirements for placement and installation of control joints in stucco. Building owners should be notified of the requirements and then allowed to decide if they want to exercise provisions of the code that allow for alternatives. This should not be your decision. You should also be fairly compensated if they require more than the plans illustrate.

-

Gold sticker on the window lists Performance Grade for this product. Windows: You should know all windows are NOT created equal. They get a Performance Grade from the manufacturer. Using a window under rate will leak, regardless of how great you flash it. While this may not be your problem, you will be dragged in and forced to defend yourself. It is easier to get confirmation upfront that the windows are properly rated for the project.

- Concrete Masonry Units: Stucco over CMU is time honored and proven. Yet many want to add a building wrap or paper to add extra water protection. This is generally a bad idea. Stucco should bond to the CMU. A slip sheet can create cracking and even reduce water resistance. Attaching the wrap to CMU will punch holes in the product that will not seal the same framing members.

-

Plastic nose corner for stucco to receive an acrylic finish coat. Know Your Corners: Corner beads and aids have plastic or steel noses. Stucco finish is cement or acrylic. Cement will want to flake off of plastic nose beads, where acrylics can rust metal noses in damp areas. Pick the nose to match the finish coat.

- Records: Keep records on when you did what. One of the first things consultants think when cracking starts (see item #2) is that you did not allow a cure time. Wait seven days minimum before applying any finish coat to your basecoat. If the builder wants you to accelerate the time, send him a letter that this “may” result in more hairline cracks in the long run. Protect yourself.

- Know ASTM: ASTM has been around a long time. The code used to describe how to install stucco, but they now opt to reference ASTM standards, and these standards are changing. You are required to follow ASTM. You can get relief on many items if you know the rules (see item #3), but you have to know what ASTM is telling you. Get a copy.

- Pre-Installation: You must walk the site and look over every possible item that could impact your stucco and its performance. Turn off your cell phone, take notes and pictures (see item # 7). Insist on a pre-install meeting with the GC, architect and owner to review expectations and concerns from all sides. Do not send threatening CYA letters, but express concern on what “might” happen. These are powerful tools, and even ones worded in a non-threatening tone can have your insurance carrier almost hugging you.

- You Don’t Know What You Don’t Know: This goes for everyone onsite. Most architects do not really understand stucco, so cut them a break. Help guide them to resources they will trust rather than try to prove you know more about stucco than they do. Because you do not know what they know, which is a lot about engineering, building science and the code. Remember you and they do not know everything.

PAINTING STUCCO

The SMA receives dozens of calls from stucco homeowners who express concerns about painting stucco and fear it will be a nightmare. This is likely the result of the prominent home improvement scam that hit the industry in the fifties and sixties. These were quick fixes to cure all siding maintenance and sounded to good to be true, because it was. This was the textured coatings boom that promised to forever eliminate painting and maintenance on your home. Even the commercials on television and radio had thrilled homeowners talking about a textured coating applied to their stucco home. The promise to eliminate the cracks and the need to ever paint again was very appealing. Seeing these textured coated homes was a bit shocking for plasterers. They sprayed the stucco, the eaves, the electrical box and the family dog if they could. They kept the masking to a bare minimum. Once done, your options to fix the nightmare were limited to strip and re-stucco. It was an expensive proposition. The hoodwinked homeowner learned a painful and expensive lesson. I suspect they told neighbors and the word got around. The craze eventually died out.

A few decades have passed and now it seems people are terrified to simply paint on stucco. Painting stucco is fine. Success depends largely on what you expect and what products are selected to paint with. Generally, paint will not cover cracking in the long term. While elastomeric coatings can hide the cracks, they can also have issues of vapor permeability. Stucco over framed walls works better if they allow moisture to escape. Sealing moisture out can have the reverse effect too, sealing it in.

Acrylic paints made specifically for stucco work well and are proven to last a long time. These products can breathe and do not trap moisture vapor in the walls. Painting new stucco is also acceptable. The pH level on newly applied stucco can be high and should be allowed to drop to 8 before painting. If an elastomeric is desired, products with a perm rating of 7 or higher are advised, and the stucco wall should be inspected by an expert in stucco to insure it is compatible for this coating. Using an elastomeric to solve water intrusion issues is a low-cost fix and generally does not fix the issue.

Fog coating is a cement-based paint. Fog coat is low cost and used only for cement finish coat stucco that is free of paint or coatings. It is a product designed to even out color inconsistencies that are inherent with cement stucco finish coats. Using fog coat to change the color of a stucco is possible and, while it can be done, painting is generally better. Finding an expert at fog coating can be challenging, and it is typically better to paint the stucco with a quality acrylic made specifically for stucco.

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA if the staff can be of any assistance.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com