MESSAGE FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

Hope everyone is looking forward to a great summer. The SMA has a lot happening. We have released the 2019 Stucco Market Report. The first industry report was in 2016 and was used extensively around the United States. The report gained respect as accurate and insightful, as being specific and targeted to our industry. The SMA was invited to the World of Concrete to demonstrate STUCCO LIVE in large part due to the 2016 Stucco Market Report. The 2019 updated version will continue this trend as it is based on data from the US Census Bureau and other market research groups. The SMA takes that data and combines it with our knowledge and can make several observations. The report is a free download at the SMA website.

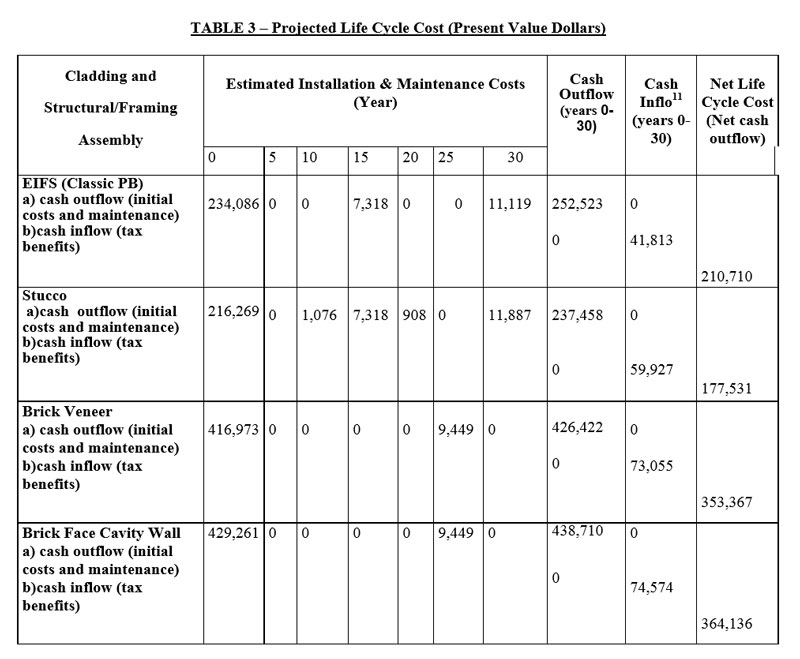

We know designers and building owners have a selection when deciding which siding for their project. We should be aware that while fire-ratings, egress and ventilation issues are not optional, the choice to use stucco certainly is. We need to keep stucco in front of them along with the fact it is the best option for a long and low maintenance life as a cladding. Stucco has a strong history of proven success. However, just a few failures have been highlighted by bad actors and some of our competitors. Some simply want stucco to just go away. They know that head to head in a fair comparison, stucco wins out. Even ASTM says so. The Cladding Life Cycle study of 1996 put cement stucco on top when compared to others (see Table 1 & 3). The US Department of Energy released two reports on hard coat stucco in 2018. One discussed one coat stucco over foam and highlighted the energy benefits. The other was a cradle-to-grave study on how stucco impacts the environment with regard to a carbon footprint. The study compared both three coat and one coat stucco. The report states, “properly done, a cement stucco should provide a useful service life of 100 years.” All this is good news and explains why other claddings try so hard to bring us down. One of our competitors has gone to the length to offer free stucco inspections. Not surprisingly, they recommend removing the stucco and replacing it with their cladding every time.

While it seems stucco will always win, that would not be an accurate picture of our market. We need to promote our industry. We need to work together to keep stucco on the minds of the designers and provide assurance that the stucco will function as promised—a long time with low maintenance. Your SMA board is on that task.

Always feel free to call the SMA for any assistance we can offer to our members.

Education/Training

We know cement stucco is the best cladding, but it has to be done correctly. We also know that it can be a real problem when installed with significant errors. But how can owners tell if the stucco is being done so it will function properly? Most experts will agree that simply adhering to ASTM is not enough and certainly no warranty. Are the materials selected correct and mixed properly? Is the installer trained and educated on stucco? It is these factors that overwhelmingly determine if stucco will function as intended.

It starts with an understanding of how stucco manages moisture. Knowledge must not be based on rumors, myths or driven by the need to make sales. The method to manage moisture can vary dramatically depending on the substrate. Masonry is not the same as framed walls as direct applied systems are not rainscreen. Stucco is versatile and can be adapted to a variety of methods when dealing with moisture. This is why stucco is more complex and can be challenging. The fact is that stucco done well will be the lowest cost cladding. Table 3 is from an ASTM study on claddings and verifies that stucco provides the lowest net life cycle cost.

SMA ON-LINE EDUCATION IS COMING

Designers and developers need to know they have hired trained and educated installers familiar with stucco. It is a must for a successful stucco installation. While apprenticeship is certainly the best method to develop an educated work force, the process can be expensive, slow and typically only can reach a small percentage of the total work force.

The SMA is working on an online education program consisting of seven training modules for installers. This can reach a wide group and do it fast. On-line training is proven to work on educating and keeping costs low. While most stucco performs intended, simple mistakes can be catastrophic. The SMA education committee believes these mistakes could be remedied if the installer simply understood the basics tenets of a hard coat stucco installation with regard to moisture. The program will put a focus on flashing and moisture to solve the more serious problems. The program also adds training tips from experienced plasterers on techniques, such as how to use the straight edge, improve hand tool production and other techniques that the older plasterers have known for decades.

On-line training may lack a hands-on component, but education is critical. The SMA contractors will be able to use the program to enhance their On-The-Job (OJT) training of all workers. On-line training offers advantages of allowing sponsoring contractors, lathers and plasterers to learn at their own time and a pace that works best for them. The education modules are put together by experts in architecture, building codes and plastering. The program will include tips on machine pumping of plaster to improve productivity. This is not a sales program, but real training, generic and comprehensive. The modules cover basics of moisture management, pros and cons of one and three coat stucco, basics in flashing, water-resistant barrier and lath installations. It also covers how to use alternates to the code.

It is important to reach young installers to start them on the right track and not let bad habits ruin our industry. The goal is pretty simple: restore faith in stucco to developers and designers in the regions of the country who have concerns about hard coat stucco. Passing exams and holding certification cards will provide assurance that stucco will last and be low maintenance. The modules will be in English and Spanish. A rigorous test must be passed to receive a certificate of completion and/or wallet card. Cost has not been determined, but be assured it will be very low.

One module will focus on supervisors for lathing and plastering. They will gain a comprehensive education on building science, codes, standards, windows, design pressure and avoiding litigation issues related to stucco. The module will cover record keeping to protect yourself in the event of litigation issues. This will make them better supervisors to the employers.

The final module that completes the circle of a successful, serviceable and sustainable stucco—the extra set of eyes. This is the third-party inspector. This module will be available to developers, designers and inspectors, but only true third-party inspectors will receive a certificate and be listed on the SMA website to inspect hard coat stucco installations. This module will include system identification, a short checklist and a review of basic details.

The benefits of the program are:

- Regain the trust of the designers, developers and public

- Contractors having better educated and productive crews

- Manufacturers expand the stucco market

- Building owners get better and cost affordable stucco

- Less litigation and support on frivolous claims

SAVE THESE DATES

Mark your calendars now to SAVE THE DATE for upcoming SMA events:

- September 23: SMA’s Annual Golf Tournament

- November 6: SMA Membership Meeting

- February 4-7 , 2020: SMA presents STUCCO LIVE! at the World of Concrete in Las Vegas

US STUCCO MARKET STUDY for 2019

If you are curious about how the stucco market is doing, look no further than the SMA’s second report on the size of the stucco market. The data is based on statistics gathered by the US government. The report is a free download on the SMA website. The executive summary: three of four markets saw stucco lose market share. One market saw an increase. More amazing was that the one market segment where stucco market share grew, it took it from the fact fiber cement siding market. The industry could use this as a model on how to win back market share. The report also reveals other claddings that seem to mesh well with stucco. The SMA plans to stay on market share analysis and keep our members informed.

If you are curious about how the stucco market is doing, look no further than the SMA’s second report on the size of the stucco market. The data is based on statistics gathered by the US government. The report is a free download on the SMA website. The executive summary: three of four markets saw stucco lose market share. One market saw an increase. More amazing was that the one market segment where stucco market share grew, it took it from the fact fiber cement siding market. The industry could use this as a model on how to win back market share. The report also reveals other claddings that seem to mesh well with stucco. The SMA plans to stay on market share analysis and keep our members informed.

Feature Articles

STUCCO & WINDOWS

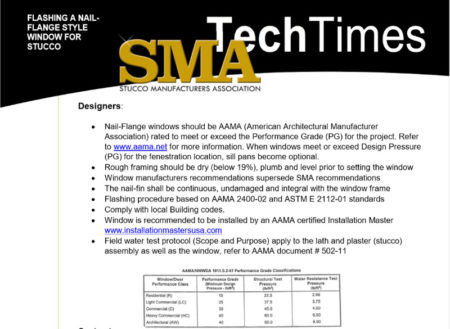

Few issues create as much controversy as how cement stucco should be terminated to a window. While many support the regional practice of every window having a casing bead and sealant joint around the entire window, some believe stucco may abut the window frame. Is this allowable, is it a defect? Contractors that support this practice have been successful in litigation defending this practice, and it can pass water tests. So which side is right? This depends on a few factors. How can we draw lines as to when and where this can be done?

The SMA has published a technical paper that can explain why, when and where. It also provides requirements, most are by others to comply with so you can be allowed to install the stucco to abut the window. Owners like the no maintenance of no sealant joints, but there are caveats. This paper was reviewed and approved by experts in codes, windows, and litigation. It should be noted that just because you have always done it that way is not a viable defense.

The SMA has published a technical paper that can explain why, when and where. It also provides requirements, most are by others to comply with so you can be allowed to install the stucco to abut the window. Owners like the no maintenance of no sealant joints, but there are caveats. This paper was reviewed and approved by experts in codes, windows, and litigation. It should be noted that just because you have always done it that way is not a viable defense.

It is important to understand that both sides of the argument make valid points. If we can accept that codes today are more performance based than ever before, designers will then have more options. The options are based on performance requirements as established by the code. Most notable is the “Components and Claddings” section of the code. This section provides guidance on selecting materials, products and design options. While contractors prefer following a regional or state regulated procedure, that practice may not meet the performance directive set by the code. It also may be adding unneeded costs. Understanding the process might help explain:

STEP ONE: The designer of record is charged to meet ASCE design requirements for Components and Claddings. This includes wind and negative pressure. Not by accident, AAMA (American Architectural Manufacturers Association) has Performance Class ratings for windows to fit and meet the Design Pressures established by ASCE.

In simple terms, an opening for window in Miami is not the same as the opening for a window in Phoenix or even central Florida. The AAMA Performance Class addresses this. Formulas rate the opening and then AAMA tests and rates the window. The two should match up, and when installed correctly, leaks will be avoided. The Stucco industry through a technical bulletin has used this same formula to establish which AAMA rated windows can have stucco directly abut the frame.

This should help provide some guidance and support on what can and cannot be done, or more accurately what can and cannot be defended in court. A final caveat is that the designer of record and window manufacturer supersedes SMA recommendations. In addition, contractors are free to institute their own “in-house” policies.

THE STRAIGHT EDGE

The straight edge, featheredge or rod is made of magnesium and used by plasterers to cut angles and make walls flat. Most industry experts agree the allowable tolerance of ¼ inch in an 8 to 10 feet run is the industry practice for quality work. While some feel this is inadequate, holding to this tolerance will produce an aesthetically pleasing wall. Very few people can discern ¼ inch in eight feet is out of plane. Tolerances stricter than this are possible, but considered unreasonable without clear direction and adequate compensation. The method of plastering alters when tolerances are required to be stricter than ¼ inch in eight feet. Most plasterers have not been trained to use the “dot and screed method.” The process is basically applying daubs of plaster or set blocks spaced within a six-foot spacing. The dots are set plumb using a string line. These will be allowed to set. Then the plasterer uses these dots or guides to fill and rod the plaster. It is similar to how tile setters “float” the mortar bed. Establish a plumb line and work from that using the rod as a screed. Coincidentally, plasterers use the term float as well, but it means something entirely different. While all this sounds basic and simple, it is time consuming. Tolerances tighter than ¼ inch in ten feet are possible, though owners should be prepared to pay extra cost for the labor required. This can vary from complexity, size and skill of the plasterers. The dot and screed plaster technique is not common, and no one should be expected to bid to these tolerances without clearly being notified this is expected. A simple and basic stucco specification and referencing a tighter tolerance should be noted by the plastering contractor and clarified. However, it should not be a tool or hammer to leverage the contractor into unfair and unjust conditions. Expecting tighter tolerances will cost more and low bids must be excluded.

The straight edge, featheredge or rod is made of magnesium and used by plasterers to cut angles and make walls flat. Most industry experts agree the allowable tolerance of ¼ inch in an 8 to 10 feet run is the industry practice for quality work. While some feel this is inadequate, holding to this tolerance will produce an aesthetically pleasing wall. Very few people can discern ¼ inch in eight feet is out of plane. Tolerances stricter than this are possible, but considered unreasonable without clear direction and adequate compensation. The method of plastering alters when tolerances are required to be stricter than ¼ inch in eight feet. Most plasterers have not been trained to use the “dot and screed method.” The process is basically applying daubs of plaster or set blocks spaced within a six-foot spacing. The dots are set plumb using a string line. These will be allowed to set. Then the plasterer uses these dots or guides to fill and rod the plaster. It is similar to how tile setters “float” the mortar bed. Establish a plumb line and work from that using the rod as a screed. Coincidentally, plasterers use the term float as well, but it means something entirely different. While all this sounds basic and simple, it is time consuming. Tolerances tighter than ¼ inch in ten feet are possible, though owners should be prepared to pay extra cost for the labor required. This can vary from complexity, size and skill of the plasterers. The dot and screed plaster technique is not common, and no one should be expected to bid to these tolerances without clearly being notified this is expected. A simple and basic stucco specification and referencing a tighter tolerance should be noted by the plastering contractor and clarified. However, it should not be a tool or hammer to leverage the contractor into unfair and unjust conditions. Expecting tighter tolerances will cost more and low bids must be excluded.

CLOSE SHAVE

Shaving the wall with the featheredge or rod is another plastering technique used on brown coat application. ASTM refers to it as “dry rodding.” The idea is to remove high spots or humps in the basecoat of plaster. This is not a dot and screed method, but simply good and common plastering. Too often the plasterer goes the semi-set basecoat and starts shaving the wall by sight alone.

They should check the wall for flatness prior to starting to shave the plaster. The checking procedure should include vertical and horizontal checks. This means checking the wall in both directions. This is the only way to truly know where and if shaving with the rod is even needed. Unnecessary shaving wastes time, money, material and leaves the wall thinner than it should be. Thinner walls are more susceptible to water penetration and cracking. To add insult to injury, the contractor must also now pay another person to have the cement droppings removed. Be smart, check that wall before you shave.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 213 379 5890

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.