FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

STUCCO LIVE! is back. The World of Concrete convention will be held June 8-10, 2021, at the Las Vegas Convention Center. As with previous years, the SMA will partner with the OPCMIA to put on live presentations of cement plaster applications. A focus will be on the new International Building Codes requirement regarding water-resistive barriers when using cement plaster. Please read Been Doing This for 30 Years (see below) to learn more.

STUCCO LIVE! has been moved to the North Hall, next to event registration. We hope you can swing by and say hello. There will also be live classroom education this year by the SMA on the lathing and plastering modules of our Stucco Training Course. Attendees to the class will qualify to take tests for the online training cards and start the certification process. Each class is 90 minutes long and suitable for novices and experts in the plastering industry.

“Been Doing This for 30 Years”

Many of our contractor members are old pros. Your experience and knowledge is invaluable, and far be it for the SMA to tell you how to do stucco. Stucco has been around a long time and, while the codes have changed, stucco has not. What you did when you were young probably still works. Even if dragged into court, your old ways can be defended, and the SMA stands with you on these tried-and-true practices.

However, 2021 is a change – a big change for stucco. Old-timers have been putting on two layers of black paper over wood-based sheathing for decades. We did it before it became part of the building code in 1982. Even with recent tweaks to the code, it was still business as usual. NOT ANYMORE.

Section 2510.6 of the 2021 International Building Code has changed all the rules. The International Residential Code has followed suit with highly similar language.

This new code language will likely put stucco at a disadvantage compared to other competitive claddings in the fight for cladding market share. Besides a likely loss of market share, the new code is confusing, and the SMA office has been contacted and asked many times for clarification. SMA contractors may have already seen the language and are likely scratching their heads. You are not alone: everyone is confused.

SMA Virtual Membership Meeting: May 12

Our SMA Member Meeting – on May 12th at 11:00 am (Pacific time) – will present our SMA Technical Paper written to cover the new IBC information and provide clarification and some guidance.

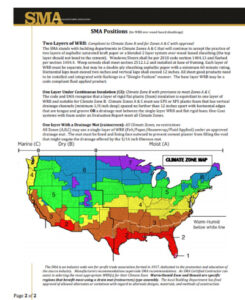

We know you have questions. Are two layers of asphaltic paper still allowed? What does Climate Zone A, B, or C mean? The reality is there are experts out there just looking to play gotcha. They want to tear into your stucco and say to the owner, “Code Violation.” This can impact designers as well. We have all seen outdated specifications, with products listed and manufacturers long out of business. It is not hard to imagine two layers Grade D being used and a consultant rubbing their hands together, thinking it is now payday for them. There are still some options left to us, just not as many as before.

The SMA will cover these options in our virtual SMA membership meeting on May 12 as we introduce our newest technical paper intended to educate and help you protect yourself. [Register in advance for this meeting. After registering, you will receive a confirmation email containing information about joining the meeting.] REGISTER NOW—>>

Silica & OSHA

The news on silica is that the OSHA has directed all regional OSHA offices a National Emphasis Program (NEP) that directs them to identify and reduce worker exposures to respirable crystalline silica (RCS) in general industry, maritime and construction. The NEP targets specific sectors expected to have the highest exposures to RCS.

As a directive from national to all regional offices, it will be taken seriously – so should all SMA employers. Verify your written exposure plan is up to date: the SMA has the new plan ready, and it is free to members. SMA also offers competent person training as part of our online Stucco Training Program that can be viewed at your supervisor’s convenience.

The rule also requires you to train or “educate” your workers on silica exposure. The SMA has a free eight-minute video to cover the very basics for workers. There is a five-question quiz. Silica dust is not a joke; neither is being fined. Protect yourself.

We also offer a Toolbox Talk sheet for the foreman which has all the topics listed that OSHA employers must convey to workers regarding silica exposure.

Make sure you are part of the SMA Silica Exposure Program and listed on the SMA website as a member. This allows you to verify to others your firm is part of the program from your smartphone. Protect yourself – it is free and easy to do as an SMA member.

TRADE TIP: Floating the Basecoat

Lath and plastering are skill-intensive trades. However, it is often overlooked that they are also knowledge-based. Knowledge can come from experiences, classrooms, or mentoring. Experiences, particularly the hard lessons of failures, are the worst and most painful method. Classroom education is excellent but sometimes better suited for trades like electricians or HVAC workers. Lath and plastering have traditionally relied on mentoring. This is when the old craftsmen teach the young the how and, most importantly, the why. Mentorship works but requires mentors and willing students. Both seem to be in short supply for the industry.

The SMA will now start a section in each newsletter called the Trade Tip. This will be a tip in the trade of lathing or plastering that old mentors would have typically passed along to those entering the craft.

This Tip deals with what the industry calls “hard floating” the membrane. Floating the brown or basecoat is meant to clean edges, terminations and prepare it for the finish coat. But floating is more than that. Floating the cement plaster should also consolidate and densify the cement plaster membrane. A properly densified ¾ inch cement membrane is more resistant to cracks and water penetration. This is not theory but fact. If this is not enough to convince nonbelievers, it is required by ASTM C-926-19 Section 7.4.2.2 “… floated uniformly to promote densification of the coat… .” Timing and tool selection are critical to float the cement plaster properly.

A hard float is one with wood, cork or neoprene material. A green, tan or red sponge is not a hard float. Floating is best done when the plaster has lost the excess mix water needed to apply the cement plaster, but before it starts to set. There is a window of opportunity for timing. A tip on timing is to push the hard-float to the wall. When it does not stick, the wall is ready to float. What must not occur is to have the cement membrane move under the pressure of float. Another image to consider is a ¾ inch raw steak. Pushing on it moves the mass as it shifts under pressure. When the excess moisture has evaporated, the shifting stops and densification can be achieved. The pressure applied to the float only has to be moderate to achieve proper densification.

Plastering is not the only industry that relies on the densification of a cement membrane to achieve a sound membrane. The cement terrazzo flooring industry has a similar practice. They pour up to two inches of pigmented cement with marble chips and no sand. They patiently wait until excess mix water begins to evaporate, and then they start to roll the terrazzo with a large, heavy roller. The act of rolling densifies and compacts the cement. Without the rolling of the cement, they would have excessive cracking and a weak terrazzo floor. They keep this practice alive by good mentoring. They know this is what leads to a long-lasting, crack- and water-resistant floor. Like plastering, ignoring a critical part of the operation can lead to problems.

The Insurance Blues

The SMA is aware our good plastering contractors see increases in liability premiums. Rates are climbing fast and high, even for those with a flawless track record concerning claims. We know many contractors see these insurance premiums impacting their bids and making it tougher to compete with other claddings.

If you think this is an accident or coincidence, it is not. Groups are trying to take the stucco market, and increased premiums coupled with fear to designers is a proven tactic. Think of what the EIFS industry went through.

We have heard you and are trying to do something about it. The SMA has been busy building a bridge with the insurance industry. The insurance industry has a research center in South Carolina where they fund testing roofs, concrete, walls, and other systems. The result is new codes, insurance policy procedures as well as policy exclusions. It is hard to understate the importance for the plastering industry to be working with them.

The SMA has offered a helping hand in the development of various walls to be tested. They appreciate the help and eventually told SMA they would work to get SMA on the committee overseeing building envelopes related to insurance issues. As far as we know, no one from the plastering industry has ever gotten this far with the insurance industry. It may be our chance to not only be heard but play a role in what happens in the future to your insurance policies and premiums.

SMA trips to South Carolina will be a strain on the SMA budget and resources. Mergers of corporate giants have impacted the revenues of the SMA’s future. In short, SMA needs our members’ help, particularly the contractors. First, you have the most skin in the game, and you have the power to make SMA a stronger voice in the industry. The SMA does not need more money from you – instead, SMA requires more suppliers and manufacturers to join our collective fight for our industry.

How can you help? Tell your material suppliers and manufacturers to join the industry and support our collaborative efforts. We can, working together, help lower insurance costs, protect contractors at the code level and make stucco a stronger market and a better market. We are all fighting for the same thing and, as their customer, they will listen to you. If they reply, “we are SMA members,” thank them for their support. If they ask “why should we join?” tell them we are ALL trying to protect our collective market. Join us and be part of the solution. The SMA believes, all together, we could be a strong and influential voice to the insurance industry.

SMA Contractor Certification

Congratulations to the latest batch of SMA Certified Contractors. They have taken the required training classes, passed the testing, and cleared with references to verify they’re part of a higher group. Architects are starting to add SMA certifications to their project specifications in South Carolina, Louisiana, Colorado, Illinois and California. The SMA board of directors approved these certifications at the last board meeting.

Congratulations to the latest batch of SMA Certified Contractors. They have taken the required training classes, passed the testing, and cleared with references to verify they’re part of a higher group. Architects are starting to add SMA certifications to their project specifications in South Carolina, Louisiana, Colorado, Illinois and California. The SMA board of directors approved these certifications at the last board meeting.

Prime Wall Systems

LLC Hutto, Texas

Onyx Building Group

El Cajon, California

SMV Stucco Inc.

Orlando, Florida

Ronparco

Euless, Texas

HPS (Home Plaster Shop) Inc.

San Clemente, California

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.