Newsletter

Summer 2024 eNews

In this addition you will meet the new SMA Board of Directors and read up on water resistant barriers.

Winter 2024 eNews

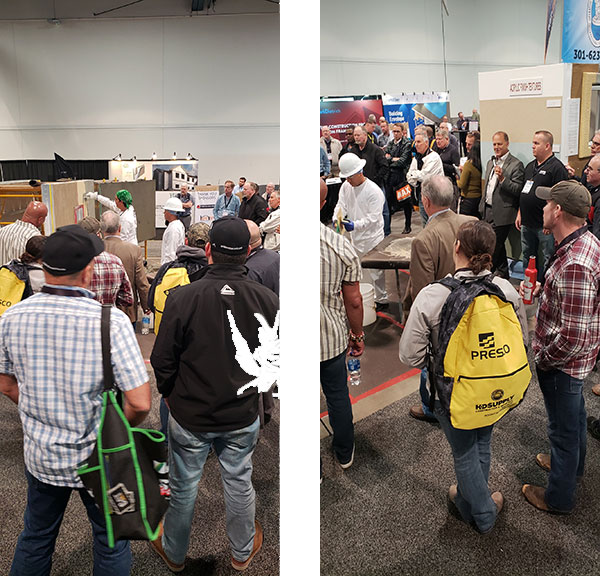

A lot is changing at the SMA and we are growing. A list of all the sponsors for the National Association of Home Builders ( NAHB) show is included and a brief write up on each of the sponsors. They not only financially support the SMA but work the SMA booth at this major trade show to promote stucco. Remember, developers and designers have cladding options, we want them to use stucco or EIFS.

Fall 2023 eNews

Summer 2023 eNews

Winter 2023 eNews

The SMA’s Winter 2023 newsletter covers promotional efforts for the stucco industry at the NAHB Internal Builders Show.. We go in depth on cement plaster on masonry walls with a history , best practices, tips and options for making an outside corner. We include information about the upcoming Membership meeting on March 28 and information about our featured speaker. There is quiz on plastering and news of the passing of industry icon.

Fall 2022 eNews

The SMA has launched a new format and style of newsletter. We call it Tech Talk. This is because technical issues are a prime concern for all in the stucco industry. This issue focuses on windows in stucco clad walls. SMA provides some basic guidelines on flashing and what the code really says about flashing. Since we are a national association for lath and plaster, we will always try to cover the regional issues as well.

Spring 2022 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

2022 SMA Board of Directors

The last few years have been tough, the SMA postponed board elections, stopped in-person meetings and canceled the annual golf tournament. The SMA is about to re-launch in-person meetings and working to making them virtual so out of state members can join in remotely. The SMA Board of Directors are from all over the United States: your current SMA Board is:

Dale Nehls, President, Quikrete

Kevin Wensel, Vice President, Omega Products

Tom Susko, Treasurer, Home Plaster Inc

Herman Guevara, Plastic Components

Dennis Deppner, Master Wall, Inc.

Gary Goodwin, K-Lath

Kevin Ordiales, Ashgrove Cement

DJ Farley, Weatherization Partners

Chip Blome, L&W Supply

The SMA board meets quarterly to discuss the industry and provide guidance to projects and direction taken by the SMA. This includes past accomplishments such as the only Silica exposure plan dedicated to plastering and adhered stone work with “Industry Objective “data on Action Levels and PEL. The six modules of on-line training for lath and plaster, including a supervisor’s class for plastering. The Stucco Market Study that uses US Census bureau data and ties it directly to the plastering industry. Tech Times Bulletins on recognized industry practices for lathing and plastering.

SMA HAPPENINGS NOW: The SMA routinely works with a variety of entities in the stucco industry and on occasion we get out to live events. The SMA recently was in Denver at Smalley and Co to do a training class on SMA Modules and certification. The even was well attended by local stucco contractors.

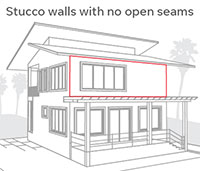

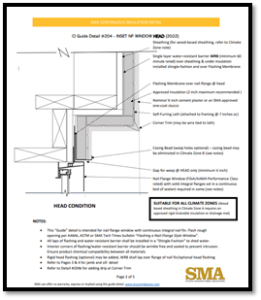

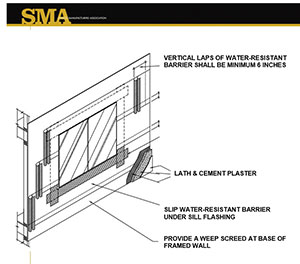

SMA UPCOMING: The SMA is working on a series of stucco details and a design guide. With three live webinars completed for Architects, the SMA has now become the leading source of information regarding lath and plaster product selection and design concerns. The request for details on stucco regarding Continuous Insulation, Rain Screen, over CMU and if the water-resistive barrier can be placed over the plastic insulation is immense. The SMA is responding with the largest library of details known in the industry. This includes tips, caveats and recommendations regarding Climate Zone. For example, Continuous Insulation Stucco for an Inset window (see graphic) is 6 pages covering an overview, head, jamb, sill, drip edge and options for stucco abutting the window frame. Details are reviewed by experts in building science, architecture and defect litigation. They are generic and considered “Guide” details to help designers create their own details that lath & plastering contractors will find constructable and cost effective.

CONTRACTOR ALERT

SMA Contractors – the new Silica Exposure Plan is available. All contractors are required by OSHA to have a Plan, perform air monitoring and have the Plan reviewed annually. The SMA does the air testing for various tasks (specific to lath/plastering and adhered masonry). You should print the plan and have that current plan available to workers, this can be inserted into your safety binder. The other requirement is to have an assigned Competent Person. The SMA provides a free on-line class for your Competent Person. There is a 25-question test to verify comprehension. A pictureID card can be issued upon passing the class upon request. There is also a tool box talk sheet that foreman can use to ensure you cover what OSHA requires be taught to your workers. The tool box form is also available in Spanish. Contact Marlene@Stuccomfgassoc.com

ASTM C1063

The SMA is frequently asked about ASTM changes to keep up to date with regard to installing lath and plaster. ASTM C 1063 is a nationally recognized standard used for the installation of lath for Portland cement plaster. It is a living standard that changes and evolves through committee action. Historically, the standard change very little. However, recently those changes have been more often and impactful.

The SMA is an organizational member of ASTM and compared the 2006 version to the 2020 version of C1063. The standards bare little resemblance to each other. The most notable changes are below. The next SMA newsletter will cover changes on C 926 (the application of cement plaster).

Most changes are related to shifting sections and edits or grammatical changes. Often new references need to be added to connect to related ASTMS. The SMA includes the section number for reference and a brief recap of the new language. SMA commentary is added if an explanation or caveat is advised.

The SMA provides this as a service to members, for exact language refer to ASTM C 1063-20.

2020 ASTM C1063-20

SUSPENDED CEILINGS: The older ASTM version had a large section on the rules for design and installation suspended cold rolled channels with various tables related to lath and plaster suspended ceilings. That language was removed and made as an ANNEX. It is still mandatory ASTM Language.

CONTROL/EXPANSION JOINTS: The most notable change related to these joints is adding a definition for each.

Section 3.2.2 now defines a control joint as a joint that accommodates movement of plaster shrinkage and curing along predetermined, usually straight lines.

Section 3.2.3 Expansion joints are defined as a joint that accommodates movement beyond plaster shrinkage and curing. There is now a NOTE or reference to design considerations shall see ASTM C926 A2.3.1.2. This C926 section states both control and expansion joints, including the integration with the water-resistive barrier shall be graphically depicted in the contract documents.

SMA Commentary: the SMA feels the new definition helps provide some guidance. In addition, adding the requirement to “graphically” depict joints on drawings (contract documents) will help contractors. The SMA agrees it is the architect who should decide where and how many control joints are needed. Including not requiring any control joints as they have the right per ASTM under “as specified” provisions. This is important as adding control joints after the plans have been approved by the city should be considered a legitimate change order item and not a design error by the designer or hidden cost assigned to the contractor. The SMA can help with this issue.

DELIVERY/STORAGE

Section 4.2.3 lath with factory paper backing shall be stored and handled to prevent puncturing the paper.

SMA Commentary: It has been reported that paper backing can be damaged during the delivery process. Suspicions are the paper-backed lath sheets may have vibrated resulting in damage to the WRB.

DESIGN/PRE-INSTALLATION:

Section 6.1.1 framing member deflection shall not exceed L/360

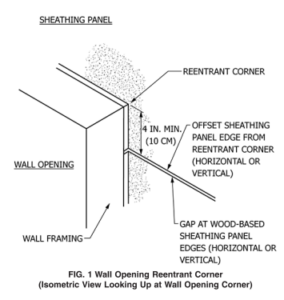

Section 6.1.4 wood-based sheathing edges shall be offset a minimum of 4 inches from wall openings (see Fig 1) .

SMA Commentary: Many installers felt this was great news, the problem is if the stucco is removed and the joint is within 4 inches of the reentrant corner, you may be deemed in nonconformance to ASTM. Walk your project and at least notify the general contractor it may be an issue. Document that you pointed it out, particularly if they refuse to fix it.

Section 6.1.5 wood framing shall have a moisture content not to exceed 19% immediately before plastering

Section 7.2.4: damage to the WRB shall be made with the same or an alternative material compatible with the water resistive barrier before plastering.

Section 7.2.5: Z furring is now considered a customized furring system and shall be engineered.

TABLE 1– Flat rib lath is no longer permitted on unsheathed walls – Hi-rib is no longer permitted on all walls.

New ASTM – Refer to ASTM C 1861 for instructions on trim accessories

Section 7.3.2.4 Except for weep screeds, designated drainage screeds with solid flanges, the water-resistive barrier shall lap the flange of the accessory.

SMA Commentary: Short Flange casing has been used for several decades with no issues. The SMA agrees that “expanded” flange casing should not be covered, but short-flange casing, reveals and other may be covered, it is more of a design and intent issues. The SMA will stand with “alternates” on a case-by-case basis.

Section 7.3.5.2 Lath to concrete or masonry. Attachment is now prescribed as 16-inch OC as if the wall is framing with ¾ inch penetration.

SMA Commentary: The SMA still stands with one fastener per square foot is an acceptable practice.

SMA writes letters on a daily basis covering a variety of issues. Including code interpretation as well as ASTM interpretation. The SMA has been very successful with building departments when an interpretation on ASTM language is needed. EXAMPLE: Both old and new ASTM C1063 call for discontinuous lath behind a control joint. Continuous lath is routinely done and is a recognized industry practice by the SMA.

JOB PROBLEM OF THE MONTH

The SMA gets calls and emails from all over North America on stucco related concerns and troubles. With modern technology and camera phones, pictures can help make the story come to life. The goal of this new section to make contractors aware of issues and hope to help them avoid these issues themselves. There is no shortage of case files.

In Florida it is common and recognized to apply a lace texture to the brown coat and then paint as the final decoration. This homeowner could not understand why the paint was peeling off the stucco. While it could be considered a paint issue, the paint pulled off the stucco texture with it.

The SMA determined there were two issues

1. The cement texture was watered down to allow for workability, and possibly an additive. This resulted in a weaker than normal cement to cement bond.

2. The paint was applied only a few days later. The high alkalinity of the cement caused what is known as pH or alkalinity burn. This resulted in a breakdown in the binders used in paint. Paint should not be applied until the pH is near neutral (7)

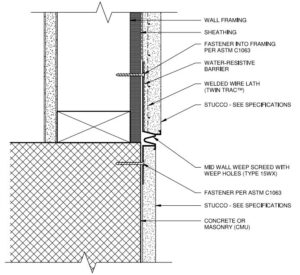

NOTE: No weep screed was used because the plaster is over a solid masonry wall. This is code compliant and unrelated to the paint/stucco failure issue.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Fall 2021 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

The Stucco Manufacturers Association (SMA) is working hard to promote stucco. Even with Covid keeping our in-person meetings to a minimum. The SMA has been doing a variety virtual meetings, classes and assistance to the architectural community. As codes and standards increase in complexity, they will need more and more help. The SMA is there for them. The SMA is a non-profit association representing the industry as a whole, not a single manufacturer, not a specific system or contractor, but all the industry. This makes the SMA a little unique and gives us influence. The SMA does not turn down or charge a fee to anyone calling in for assistance. Architects, general contractors and building owners look at the SMA as a kind of Consumer Reports group on steroids. The SMA also works hard to make sure members products and services are listed and referenced in project specifications. The SMA will recommend specific products when a perfect fit is noted or asked if there is a recommendation, this happens a lot.

Many designers are finding the SMA Contractor certification program particularly useful. Only a state license with the lowest bid is not much assurance the contractor is qualified to do the work. The SMA now has certified contractors in four states and expanding. Recently we even had an inquiry from England. The reviews of the six modules of training are overwhelmingly positive. The most impactful and relevant comments come from installers ( lathers and plasterers) who say they learned something new. If you have not checked out the modules yet, they are free, yes free to everyone to watch (online training program). The SMA felt it was important to make an effort to standardize industry practices, yet still allow for regional preferences. The goal is to make this a wide spread program that is nationally recognized and there is a powerful reason why. The SMA recently sat with one of the overall Insurance industries board of directors and she thought our program was great and compared it to the national roofing industry program, those contractors enjoy reduced premiums as the insurance industry feels more confident in their work. However, that group is more wide-spread as compared to us as we are just getting started. The insurance industry is looking to us to hopefully make a difference. Promoting the SMA certification program is a step to reduced risk for them and lower insurance premiums for you. What is the cost of certification? It is essentially free to SMA members. The future is in your hands, it is your industry and action or inaction will direct us all. (How to become Certified)

INDUSTRY NEWS

INDUSTRY NEWS

New 2021 code- the new International codes have significant changes when cement plaster is applied over wood-based sheathing. For the first time the codes mandate variations in application and design with regard to Climate Zones. The climate zones would technically be more appropriately called “moisture” zones. There are three of these zones for the United States A (moist), B (dry) or C (marine). The SMA has been giving classes to installers and even building departments on this new change. You maybe thinking “I have not seen this on my project, how can this be true?” The code cycle is every three years and the international codes come out first with state and local codes following in the next few years. So, get ready, it is coming as it has been written and published, just yet to be enforced. If you have not downloaded the SMA Tech Times bulletin on this topic, consider doing this soon, at least before the code hits you in the face. A word of caution, in litigation ignorance of the law, particularly when it is very industry specific, is not typically a viable defense. Be informed, be prepared.

MARKET NEWS

EAST vs WEST

While drywall is used with great regularity around the United States, stucco is only popular in some pockets or regions. Many believe that stucco is only suitable for warm dry climates. This explains why stucco is so popular in Southern California, Texas and Florida. Yet, it is hard to imagine Florida as dry. It maybe more accurate to state some believe stucco is NOT suitable for snow regions of the country. Due to freeze thaw concerns. However, the Swiss and Germans have used and continue to use cement stucco all the time. The truth is stucco works in all climates. High moisture areas simply require a little more attention to flashings, cold or snow regions require thinking of snow drifts, but it is not difficult to make stucco work anywhere.

The southern sections of east and the west coast are both popular stucco markets. With contractors’ members in all regions, the SMA must be adaptable to each region. The sad truth is that many experts in a region feel their way is the “only” way to install lath and plaster. This is what makes the ASTM committees a hot bed of in-fighting. They rarely agree on anything and seem unwilling to capitulate the other side has a proven regional practice. This explains why many contractors on both coasts routinely turn to the SMA for help with clarification on standards and allowed industry practices. Some feel we need a single inflexible standard with no allowances for regional practices, but how could that possibly work? Adding to the fact the international code has now set a precedent of regional practices by implementing the three climate zones with very different installation practices, it seems impossible. Whether we like it or not, there are regional practices and preferences. Most on the east coast refuse to use woven wire lath and that is fine. But the SMA will not state it is illegal. Here are some generalities about each coast of the USA regarding stucco.

WEST COAST: Pumping cement plaster is king in the west. The crews have mastered the art of machine application and the result is lower installed costs on basic residential tract work. It is so low, that vinyl siding has a hard time competing against stucco. This in turn allows custom homes to look at smooth trowel plaster. The added cost of the base and mesh to reduce cracks have made smooth trowel plaster the once hated finish to a preferred and affordable finish in the high end markets. One coat stucco is also gaining popularity , mostly in the residential market due to the Tongue and Groove insulation providing continuous insulation. More good news, these systems have been tested and meet the more stringent code requirements for enhanced drainage for Climate Zones A and C. Commercial work is primarily three coat stucco for durability and the inherent fire ratings in the code. While there are slight changes on the west coast from south to north, installations are similar. Stucco is just less popular as you move further north up the coast. Ironically, the use of the plaster pumps is also less popular moving up north and can impact installed costs.

EAST COAST: The similarity for the east coast is the stucco market shrinks moving north, but does not seem to be related as much to machine production rates as other factors. Florida is the big market in the east. Unlike California, there is a major difference in application from south to north. In the southern part of the state, walls are mostly Concrete or CMU. The plaster becomes a parge coat and a finish may or may not be applied. Most stucco is painted. Elastomeric coatings are fairly popular. The vapor drive is opposite of the rest of the country, so that may be the better method of installation in that region. Moving north in Florida, projects start to see stucco on framing. It is also common to have the first floor CMU and the second-floor wood framing. This resulted in a massive number of leaks as the designers and installers failed to install a functioning weep device at the transitional floor line. That has been rectified and it is now common to use the PVC mid-wall weep screed as pictured. Both Plastic Components and Clark Dietrich manufacturer these products. They both have proven effective to stop the leaks.

TECHNICAL CORNER

COLD WEATHER PLASTERING

Cold weather is approaching. In parts of Canada, tenting the work is common practice. In really cold areas, they wait until Spring. It is true that freezing cement is a potential issue and should be avoided. Freezing stops the hydration process. This means the cement plaster does not get hard. The fear of freezing cement so great that manufacturers and ASTM prescribe that plaster should not be applied in temperatures below 40 degrees F. The SMA has experience in cold weather plastering with projects in Alaska, Minnesota and more moderate cities like Seattle. Many regions get cold, really cold and plastering should stop. However, much of the country is like Seattle. A kind of mix of sleet and frost. A Seattle pattern can be just below 40 F in the night and over 50F during the day. This is not an issue for Portland cement plaster. Cement plaster does not freeze easily. The temperature would have to be below freezing for at least a few hours for the cement to freeze. Even if it did, it can often be brought back the next day with minimal damp curing when temperatures climb above 40F. This also does not impact the cement plasters service life or its fire rating.

Acrylic finish coats are another story. They must be allowed to dry. Cement sets as it cures, we tend to say acrylics dry to a cure. While not technically accurate, it is better thinking this way. In addition, the acrylic dries from the outside in, as opposed to cement that cures from the inside out. What can happen is the acrylic gives what is called a “false set” on the surface. It may feel hard and cured, but is still soft against the cement plaster basecoat. If temporary protection protecting the acrylic finish is removed to soon, the set (cure) will never take place. The first rain or water can create bubbles or wash the acrylic off the basecoat. See picture . This is why plasterers in regions with temperatures than dip near freezing are very careful about using acrylic finishes in cold weather.

SMA BOARD OF DIRECTORS 2021

At the most recent SMA board of Directors meeting , Rick Durham was selected to be President of the SMA. Rick is from Texas and has a long history in the plastering industry. He was a plasterer and is a valuable resource to many of the contractors in his region. Rick has served on the board for the Texas Lath and Plastering Contractors Assoc (TLPCA) . as well as the National One-Coat Stucco Assoc (NOCSA). Currently Rick is running EZ Wall Concentrate, a producer of quality bagged cement products including basecoat stucco and tolling operations. Rick Durham believes in stucco and hopes to unite our efforts to preserve and grow the stucco market. He focuses on market share for our industry and limiting risks that plastering contractors face. His expertise and leadership will be helpful to guide the SMA into this new decade. Your SMA board of Directors:

Rick Durham- President (Texas)

Kevin Wensel-Vice President (California)

Justin Fleming- Treasurer (Florida)

Thom Susko – (California)

Herman Guevarra – (Florida)

Gary Goodwin – (Arizona)

DJ Farley – (California)

Dale Nehls – (Colorado)

NEWEST SMA CERTIFIED CONTRACTORS

Orlin’s Stucco – Florida

Prime Wall Systems – Texas

Onyx Group – California

Ronparco -Texas

SMV Stucco – Florida

HPS llc – California

Not Certified? It has benefits, strengthens our industry and works to lowering risk and reduced insurance premiums.

Get certified for the industry and yourself.

Please feel free to call the SMA office if we can be of any help.

Respectfully,

Mark Fowler , Executive Director

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Administrator

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Spring 2021 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

STUCCO LIVE! is back. The World of Concrete convention will be held June 8-10, 2021, at the Las Vegas Convention Center. As with previous years, the SMA will partner with the OPCMIA to put on live presentations of cement plaster applications. A focus will be on the new International Building Codes requirement regarding water-resistive barriers when using cement plaster. Please read Been Doing This for 30 Years (see below) to learn more.

STUCCO LIVE! has been moved to the North Hall, next to event registration. We hope you can swing by and say hello. There will also be live classroom education this year by the SMA on the lathing and plastering modules of our Stucco Training Course. Attendees to the class will qualify to take tests for the online training cards and start the certification process. Each class is 90 minutes long and suitable for novices and experts in the plastering industry.

“Been Doing This for 30 Years”

Many of our contractor members are old pros. Your experience and knowledge is invaluable, and far be it for the SMA to tell you how to do stucco. Stucco has been around a long time and, while the codes have changed, stucco has not. What you did when you were young probably still works. Even if dragged into court, your old ways can be defended, and the SMA stands with you on these tried-and-true practices.

However, 2021 is a change – a big change for stucco. Old-timers have been putting on two layers of black paper over wood-based sheathing for decades. We did it before it became part of the building code in 1982. Even with recent tweaks to the code, it was still business as usual. NOT ANYMORE.

Section 2510.6 of the 2021 International Building Code has changed all the rules. The International Residential Code has followed suit with highly similar language.

This new code language will likely put stucco at a disadvantage compared to other competitive claddings in the fight for cladding market share. Besides a likely loss of market share, the new code is confusing, and the SMA office has been contacted and asked many times for clarification. SMA contractors may have already seen the language and are likely scratching their heads. You are not alone: everyone is confused.

SMA Virtual Membership Meeting: May 12

Our SMA Member Meeting – on May 12th at 11:00 am (Pacific time) – will present our SMA Technical Paper written to cover the new IBC information and provide clarification and some guidance.

We know you have questions. Are two layers of asphaltic paper still allowed? What does Climate Zone A, B, or C mean? The reality is there are experts out there just looking to play gotcha. They want to tear into your stucco and say to the owner, “Code Violation.” This can impact designers as well. We have all seen outdated specifications, with products listed and manufacturers long out of business. It is not hard to imagine two layers Grade D being used and a consultant rubbing their hands together, thinking it is now payday for them. There are still some options left to us, just not as many as before.

The SMA will cover these options in our virtual SMA membership meeting on May 12 as we introduce our newest technical paper intended to educate and help you protect yourself. [Register in advance for this meeting. After registering, you will receive a confirmation email containing information about joining the meeting.] REGISTER NOW—>>

Silica & OSHA

The news on silica is that the OSHA has directed all regional OSHA offices a National Emphasis Program (NEP) that directs them to identify and reduce worker exposures to respirable crystalline silica (RCS) in general industry, maritime and construction. The NEP targets specific sectors expected to have the highest exposures to RCS.

As a directive from national to all regional offices, it will be taken seriously – so should all SMA employers. Verify your written exposure plan is up to date: the SMA has the new plan ready, and it is free to members. SMA also offers competent person training as part of our online Stucco Training Program that can be viewed at your supervisor’s convenience.

The rule also requires you to train or “educate” your workers on silica exposure. The SMA has a free eight-minute video to cover the very basics for workers. There is a five-question quiz. Silica dust is not a joke; neither is being fined. Protect yourself.

We also offer a Toolbox Talk sheet for the foreman which has all the topics listed that OSHA employers must convey to workers regarding silica exposure.

Make sure you are part of the SMA Silica Exposure Program and listed on the SMA website as a member. This allows you to verify to others your firm is part of the program from your smartphone. Protect yourself – it is free and easy to do as an SMA member.

TRADE TIP: Floating the Basecoat

Lath and plastering are skill-intensive trades. However, it is often overlooked that they are also knowledge-based. Knowledge can come from experiences, classrooms, or mentoring. Experiences, particularly the hard lessons of failures, are the worst and most painful method. Classroom education is excellent but sometimes better suited for trades like electricians or HVAC workers. Lath and plastering have traditionally relied on mentoring. This is when the old craftsmen teach the young the how and, most importantly, the why. Mentorship works but requires mentors and willing students. Both seem to be in short supply for the industry.

The SMA will now start a section in each newsletter called the Trade Tip. This will be a tip in the trade of lathing or plastering that old mentors would have typically passed along to those entering the craft.

This Tip deals with what the industry calls “hard floating” the membrane. Floating the brown or basecoat is meant to clean edges, terminations and prepare it for the finish coat. But floating is more than that. Floating the cement plaster should also consolidate and densify the cement plaster membrane. A properly densified ¾ inch cement membrane is more resistant to cracks and water penetration. This is not theory but fact. If this is not enough to convince nonbelievers, it is required by ASTM C-926-19 Section 7.4.2.2 “… floated uniformly to promote densification of the coat… .” Timing and tool selection are critical to float the cement plaster properly.

A hard float is one with wood, cork or neoprene material. A green, tan or red sponge is not a hard float. Floating is best done when the plaster has lost the excess mix water needed to apply the cement plaster, but before it starts to set. There is a window of opportunity for timing. A tip on timing is to push the hard-float to the wall. When it does not stick, the wall is ready to float. What must not occur is to have the cement membrane move under the pressure of float. Another image to consider is a ¾ inch raw steak. Pushing on it moves the mass as it shifts under pressure. When the excess moisture has evaporated, the shifting stops and densification can be achieved. The pressure applied to the float only has to be moderate to achieve proper densification.

Plastering is not the only industry that relies on the densification of a cement membrane to achieve a sound membrane. The cement terrazzo flooring industry has a similar practice. They pour up to two inches of pigmented cement with marble chips and no sand. They patiently wait until excess mix water begins to evaporate, and then they start to roll the terrazzo with a large, heavy roller. The act of rolling densifies and compacts the cement. Without the rolling of the cement, they would have excessive cracking and a weak terrazzo floor. They keep this practice alive by good mentoring. They know this is what leads to a long-lasting, crack- and water-resistant floor. Like plastering, ignoring a critical part of the operation can lead to problems.

The Insurance Blues

The SMA is aware our good plastering contractors see increases in liability premiums. Rates are climbing fast and high, even for those with a flawless track record concerning claims. We know many contractors see these insurance premiums impacting their bids and making it tougher to compete with other claddings.

If you think this is an accident or coincidence, it is not. Groups are trying to take the stucco market, and increased premiums coupled with fear to designers is a proven tactic. Think of what the EIFS industry went through.

We have heard you and are trying to do something about it. The SMA has been busy building a bridge with the insurance industry. The insurance industry has a research center in South Carolina where they fund testing roofs, concrete, walls, and other systems. The result is new codes, insurance policy procedures as well as policy exclusions. It is hard to understate the importance for the plastering industry to be working with them.

The SMA has offered a helping hand in the development of various walls to be tested. They appreciate the help and eventually told SMA they would work to get SMA on the committee overseeing building envelopes related to insurance issues. As far as we know, no one from the plastering industry has ever gotten this far with the insurance industry. It may be our chance to not only be heard but play a role in what happens in the future to your insurance policies and premiums.

SMA trips to South Carolina will be a strain on the SMA budget and resources. Mergers of corporate giants have impacted the revenues of the SMA’s future. In short, SMA needs our members’ help, particularly the contractors. First, you have the most skin in the game, and you have the power to make SMA a stronger voice in the industry. The SMA does not need more money from you – instead, SMA requires more suppliers and manufacturers to join our collective fight for our industry.

How can you help? Tell your material suppliers and manufacturers to join the industry and support our collaborative efforts. We can, working together, help lower insurance costs, protect contractors at the code level and make stucco a stronger market and a better market. We are all fighting for the same thing and, as their customer, they will listen to you. If they reply, “we are SMA members,” thank them for their support. If they ask “why should we join?” tell them we are ALL trying to protect our collective market. Join us and be part of the solution. The SMA believes, all together, we could be a strong and influential voice to the insurance industry.

SMA Contractor Certification

Congratulations to the latest batch of SMA Certified Contractors. They have taken the required training classes, passed the testing, and cleared with references to verify they’re part of a higher group. Architects are starting to add SMA certifications to their project specifications in South Carolina, Louisiana, Colorado, Illinois and California. The SMA board of directors approved these certifications at the last board meeting.

Congratulations to the latest batch of SMA Certified Contractors. They have taken the required training classes, passed the testing, and cleared with references to verify they’re part of a higher group. Architects are starting to add SMA certifications to their project specifications in South Carolina, Louisiana, Colorado, Illinois and California. The SMA board of directors approved these certifications at the last board meeting.

Prime Wall Systems

LLC Hutto, Texas

Onyx Building Group

El Cajon, California

SMV Stucco Inc.

Orlando, Florida

Ronparco

Euless, Texas

HPS (Home Plaster Shop) Inc.

San Clemente, California

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Fall 2020 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

I think it is fair to say that 2020 sucks, and we cannot wait for it to end. The SMA hopes we can go back to normal sometime in 2021, but even that is not guaranteed. I run two national associations for construction trades, and it is clear: things will change. Similar to 9/11, this too will pass but likely shift our landscape forever. Most likely, those who fail to adapt will suffer. Some changes will be dramatic, others subtle, but at the end to this decade, they will all be clear to us. The question is, what will we be saying as we look back? Did we see the trend shifts and make the required adjustments? I hope you think seriously and agree we need to be on it or get run over. The Code Update section is an excellent example of changes likely to come.

It is not all bad news. The SMA board has been on the forefront to make industry changes, not to survive but thrive in the coming decade. This newsletter will focus on the various SMA programs. Some are in place, like the Silica Compliance Program; others are new and just kicking off, such as the SMA Stucco Training Modules and the SMA Contractor Certification Program. We will also introduce you to the SMA Quality Assurance Program that is under development. This newsletter will cover each program and be your guide to where the SMA thinks the industry is going and how the SMA can help your stucco and your business succeed.

The SMA plans a Webinar soon to explain these programs in greater detail and answer member questions.

SMA Silica Compliance Program

The SMA Silica Compliance Program continues to be an industry-leading program. Respirable silica dust is a serious issue. Just as serious is the employer’s responsibility to protect their employees. The SMA has a proven written exposure plan for your company – specific to plastering and adhered masonry. Our YouTube channel has the “Silica Awareness” video covering the minimum items you must cover with all employees. The SMA also offers “Competent Person” training and a card to verify the training. All in the Silica Program is FREE to SMA contractors, including the required written exposure plan, the toolbox talk sheets in English and Spanish and the training we offer with testing. Consider the SMA Silica Program similar to auto insurance. Getting in after an OSHA fine is the same as asking your agent for insurance after the auto accident, too late now. Being an SMA member helps protect you.

Why a Stucco Training Program?

Why do we need this? First, it is still a free country, and no one will force you to anything against your will. But most seem to agree, we do not have the training programs required, and while these may not be perfect, they are a good start.

Stucco market share grew and then suffered a setback with leaky buildings. Of course, all buildings leaked, but stucco was an easy target for litigation. Not all regions of the country were impacted equally, nor are the after-effects the same. Why?

- Stucco is easy to attack because it is site fabricated.

- Stucco has more variables than other claddings.

- The industry has lacked a collective voice and fragmented.

- We have some bad actors out there. And since low bid is king, they can continue.

- Codes and standards are changing fast, making it hard to keep up.

The result is stucco is the easiest cladding to attack and hard to defend with mixed messages, codes changing as fast you can blink. The workers in the field hardly stand a chance, as well as the supervisors.

The SMA set out to help with one voice, acknowledging regional allowances for the industry and a solid defense plan. The SMA has put the modules (classes) on the new SMA YouTube channel. Clicking like and subscribing helps the SMA and the industry be a collective voice. The first step is simply a couple of clicks that cost us nothing; we hope you start there to help our industry.

SMA Online Video Training:

Modules 1-5 – Lath & Plaster

The SMA Online Video Training has five 30-minute training modules on lath and plastering. Modules 1 and 2 are lathing, 3 is material, and 4 and 5 are plastering. It is NOT merely code memorization; these are trade tips for the workers in the field. The SMA believes it is critical that trade workers understand the WHY. Why lap housewraps/paper to flashing and how? Why you should counter flash kick-outs? Why hard float the brown coat? We also include trade tips, such as cutting casing beads more efficiently, improving production using the hawk and trowel, and how to cut angles in wet cement plaster. Module 4 covers the plaster pumps, different types, how they work, and tips on using these production masters. Module 5 covers the finish coat. Focus is devoted to doing a quality smooth trowel cement finish.

Overall, these modules will be great for those getting started in lathing and plastering as well as seasoned pros. They are all free to the public on the Stucco Manufacturers Association YouTube channel and on our website.

Overall, these modules will be great for those getting started in lathing and plastering as well as seasoned pros. They are all free to the public on the Stucco Manufacturers Association YouTube channel and on our website.

For those wanting a training card to verify taking the class, the SMA can offer a picture card with an SMA registration # after passing a 50-question test on the website. The processing fee is $75 per test. If a person wants to take lath and plaster (100 questions), the fee is $100. We allow a person, should they fail, to re-take the test at no extra charge, but they must wait 30 days. The courses passed are listed on the back of the card.

Module 6 – Supervision

This is the SUPERVISOR course. The Supervisor course includes Modules 1 through 5. Module 6 (Supervisor) includes a manual for lath and plaster supervisors and is the gateway to certifications. This course material covers leadership skills, documentation of events, building science, and how to use SMA technical bulletins to do better stucco and protect the building owner and the contractor. Supervisor training/education has never been available to the stucco industry. The course material has been vetted by experts in defect litigation, building science, and leadership skills, with a focus on lath and plastering. Module 6 is the gateway to SMA Contractor Certification.

SMA Contractor Certification

The first requirement of the SMA Contractor Certification is to have an SMA supervisor on staff. The process verifies the leadership has been trained and educated on lath and plaster. A contractor can send an employee or take the test themselves. If the SMA supervisor leaves, certification will follow that supervisor. Contractors should consider who they want to have approved. SMA Contractor Certification requires being in business for over two years with verifiable references and includes a background check. Approval is by the SMA Board of Directors, and the board can revoke certification. The cost is $500 for SMA members. However, to thank our contractor members, the SMA offers to put the $500 certification fee toward your next year’s annual dues. This essentially means it costs current SMA contractor members nothing to get certified. It is the board of directors saying thank you for supporting the program and the SMA. Upon approval by the SMA board, the contractor can use the “Certified” logo on letterhead, equipment, or other approved places. An SMA letter will be sent to verify you are SMA certified that you could use to submit with bids. Certification demonstrates your company is a step above the competition. Because the low bid is not a fair selection process. Non-SMA members can become certified for $1495.

The first requirement of the SMA Contractor Certification is to have an SMA supervisor on staff. The process verifies the leadership has been trained and educated on lath and plaster. A contractor can send an employee or take the test themselves. If the SMA supervisor leaves, certification will follow that supervisor. Contractors should consider who they want to have approved. SMA Contractor Certification requires being in business for over two years with verifiable references and includes a background check. Approval is by the SMA Board of Directors, and the board can revoke certification. The cost is $500 for SMA members. However, to thank our contractor members, the SMA offers to put the $500 certification fee toward your next year’s annual dues. This essentially means it costs current SMA contractor members nothing to get certified. It is the board of directors saying thank you for supporting the program and the SMA. Upon approval by the SMA board, the contractor can use the “Certified” logo on letterhead, equipment, or other approved places. An SMA letter will be sent to verify you are SMA certified that you could use to submit with bids. Certification demonstrates your company is a step above the competition. Because the low bid is not a fair selection process. Non-SMA members can become certified for $1495.

SMA Quality Assurance Program

This program is currently under development. The concept is pretty simple. The SMA Certified Contractor will receive forms and checklists that they may use. The program is not mandatory. The form verifies materials, flashing, and procedures, with room for comments and pictures. The report can be printed and given to the building owner. The report can be used later should questions arise, particularly when the building is sold. The report can provide future inspectors a comfort level with what you did under the stucco.

Besides sending this to the building owner, a copy may be sent to the SMA vault. The SMA will keep these reports for ten years. At that time, the statute of limitations expires, and records are far less critical. Should a consultant opt to file a lawsuit against the SMA Certified Contractor who has put in a file for that project, the SMA will have a record and provide comments as an authoritative source on industry practices. The SMA opinion can help contractors and their insurance carriers better protect them against frivolous lawsuits. For those worried about the program, it is 100% voluntary, but taking pictures (which the SMA recommends, which locations to take them) can often help contractors spot minor defects as well, allowing them to make needed adjustments. If work under the stucco is done per industry practice, this evidence can provide a strong case that intrusive investigation is not warranted. Because once they start cutting into the stucco, it tends to be a point of no return. The forensic group will tend to want to justify the reasons for cutting into the stucco. The report (pictures) can help identify errors, be a good defense and provide a comfort level to others.

CODE UPDATE: ALL ABOUT THE WRB

For decades it was pretty simple for plastering contractors; we all used asphalt-treated kraft paper water-resistive barriers (AKA “black building paper”). We knew there was a Grade D for stucco, and it could be 10, 30 or 60 minute-rated. We also knew we had to put two layers over wood-based sheathings. Get the laps right, and you’re good to go. That world is long gone. Today there is a mind-numbing amount of selections of WRB products, and the codes have changed significantly. You need to read and understand this.

COMMERCIAL

International Building Code (IBC) section 2510.6 (commercial) has replaced the term Grade D with ASTM references. Grade D is now referred to as compliant to ASTM E 2556. Type I is 10-minute, and Type II is 60-minute Grade D.

2018 Code: 2510.6 Water-resistive barriers.

Water-resistive barriers shall be installed as required by Section 1403.2 and, where applied over wood-based sheathing, shall include a water-resistive vapor permeable barrier with a performance at least equivalent to two layers of water-resistive barrier complying with ASTM E2556, Type I. The individual layers shall be installed independently such that each layer provides a separate continuous plane and any flashing (installed per accordance with Section 1404.4) intended to drain to the water-resistive barrier is directed between the layers.

SMA Policy: This language, while well intended, is confusing and not always possible when two layers of water-resistive barrier are applied and integrated with flashings. Besides making it virtually impossible in cases to fully comply, double-layer kraft paper has been used for several decades with no evidence that this method of application has been an issue for water intrusion. Fortunately, there are 2 (two) exceptions to the above code requirement that provide relief and options.

Exceptions:

1. Where the water-resistive barrier that is applied over wood-based sheathing has a water resistance equal to or greater than that of a water-resistive barrier complying with ASTM E2556, Type II and is separated from the stucco by an intervening, substantially nonwater-absorbing layer or drainage space.

2. Where the water-resistive barrier is applied over wood-based sheathing in a Climate Zone 1A, 2A or 3A, a ventilated air space shall be provided between the stucco and the water-resistive barrier.

Exception 1: The SMA sees this as primarily allowing one layer of water-resistive barrier to be substituted for rigid foam or a drainage mat. We fully support this option. One-coat stucco has been doing this for decades with great success. Some experts feel that this excludes asphaltic paper. The SMA does not agree and states that asphaltic kraft paper (Grade D) absorbs “minor” amounts of water, enough to wrinkle, but do not “substantially” absorb water. To verify this claim, if substantial amounts of water were absorbed into the kraft paper, the thin scratch coat of fresh cement would never cure as too much water would be taken from the cement. Flash drying in cement scratch coat occasionally occurs, but only in hot, dry, and windy weather. It is the weather that dissipates the moisture. This means the separate layer rule is also negated for asphaltic papers. Mixed water-resistive barrier products would require two separate planes. The SMA recommends that these assemblies have the house wrap product applied first and a layer of ASTM E 2556 over that.

Exception 2: These climate zones are established by ASHRAE. In short, they cover most of Florida, Texas, Louisiana, South Carolina, Mississippi, Georgia, Alabama, and parts of North Carolina, Arkansas, Tennessee, and Oklahoma. Your architect/designer should verify the zone. The ventilated space means with assembly requires a drainage mat under the stucco when applied to wood-based sheathings. California is currently exempt, but this requirement for stucco is likely coming in the next few years.

RESIDENTIAL

The International Residential Code (IRC) language on stucco WRBs (section R703.7.3) is very similar to the commercial (IBC) code, except it still references Grade D paper. It also has exceptions as well. Exception number 2 replaces the term “ventilated air space” with a “designed drainage space.” They have also left out any Climate Zone references, thereby adding even more confusion.

The SMA understands that the IBC is intended for commercial structures by covering more relevant buildings such as multistory, hospitals, and schools. The IRC is strictly for duplexes and single-family homes.

This now introduces the term “Drainage Space.” Fortunately, ASTM E2266 is a standard that covers the “drainage wall.” Per ASTM E2266:

A Drainage Wall: is a wall system in which the cladding provides a substantial barrier to water intrusion, but which also incorporates means for dissipating water that may circumvent the cladding. For purposes of this standard a drainage wall is assumed to incorporate a concealed weather-resistive barrier¹ over which drainage, away from water-sensitive components of the wall, may occur. In addition, to drainage behind the cladding, evaporation may play an important role in dissipating moisture in some types of claddings.

This seems to be written to define stucco with building paper over framed walls specifically. The cement plaster, properly mixed and applied, sheds the vast majority of the water. We accept that incidental water can circumvent the stucco and incorporate a concealed water-resistant barrier. Cement stucco also absorbs moisture and dissipates that moisture to the exterior. Some consultants refer to this a “reservoir” cladding. While some think of this as a negative, ASTM E2266 makes it a positive feature as Portland cement, unlike water-sensitive materials, is relatively unaffected by water.

FOAM SHEATHING

As Continuous Insulation continues to gain favor under exterior claddings, it stands to reason that codes have adjusted as well. Currently, the International Building and Residential Codes have many references to Foam Plastic sheathing; most are about cladding attachment and energy savings.

Exception 1: The code supports the use of rigid foam as replacing one of the two layers of the water-resistive barrier when two are required. While not required by the IBC, it is generally recommended to use a tongue and groove or a rigid board that incorporates drainage channels on the backside. The SMA rationale is that this is required for one-coat stucco through the Evaluation Report(s), and makes sense the commercial code is generally more restrictive due to the structure and occupancy coverage.

Another option is to use a drainage mat behind and the rigid foam to enhance drainage. Drainage between the foam sheathing and cement plaster applied to the foam will not occur. This is noted in the Portland Cement Association (PCA) Plaster/Stucco Manual under Coolers and Walk-in Freezers: “Portland Cement plaster bonds tenaciously to most insulation, such as polyurethane, polystyrene, and cork.” This tenuous bond, while structurally beneficial, will not allow for drainage. The SMA considers bonding of cement plaster to rigid insulation similar to stucco over masonry substrates. This also explains why most plaster bureaus encourage the water-resistant barrier to be under rigid insulation.

CONCLUSION

Always follow what the designer has specified. If you have concerns that the design may not meet code, you should request verification that it does indeed meet current code, but then proceed as directed. NEVER switch out or alter the water-resistive barriers to what you think is code minimum or put in products that you believe exceed the code for everyone’s protection without approval. DO NOT DESIGN: point out potential concerns, use SMA documentation to support your claim, and document the response. Protect yourself.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Summer 2020 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

The year 2020 has not been what we expected. This pandemic has flipped just about everything upside down. Meetings canceled, offices empty and the extra cost to do just about any task seems to push the limit of just breaking even on a project. However, we will get through this as we have gotten through the depression, the great recession and the housing collapse. While finding a silver lining seems hard, there may be one out there. Your competitors—who are poorly funded, unskilled and should not be in business—may not be around to see 2021.

The SMA and its manufacturers want to help you succeed. One issue that has come up over and over is that the “trunk slammer” down the street will now be cheaper. They will claim they are the best value, and we all know the low price is hard to sway builders away from. But the SMA may be able to help

Introducing the SMA Certified Contractor. A simple fact is that many designers, builders and home owners want stucco but are scared it will be done wrong. And with only the price to go on, they typically pick the lowest bid. This is because even the low bidder is going to sell themselves as the most qualified. NOW, there will be a way to differentiate yourself from the low bidder. You are SMA certified.

Introducing the SMA Certified Contractor. A simple fact is that many designers, builders and home owners want stucco but are scared it will be done wrong. And with only the price to go on, they typically pick the lowest bid. This is because even the low bidder is going to sell themselves as the most qualified. NOW, there will be a way to differentiate yourself from the low bidder. You are SMA certified.

Learn more about our certification program here…

The program is designed to be national. It covers regional practices and variations between various states. What makes this program unique is that it is NOT merely code or standards memorization. The purpose of the program is to know WHY you do something and then HOW best to get it done. It is for the new lather and plasterer as well as the seasoned pro. We promise, the pro will learn something from watching the video modules. A Union-trained lather watched the video: “ I learned a lot and will lath my jobs differently in the future, all lathers should watch this program.”

See also the SMA’s introductory “Stucco Certification” training video [right sidebar] to learn more, or log onto the SMA YouTube channel and start watching. It is free.

SMA Board of Directors

Fall is the time we elect new officers to the SMA Board. There has never been a time that being on the board will be more impactful. The SMA Certified Contractor Program will require contractors to meet a variety of criteria. The final hurdle for the stucco contractor wanting approval for SMA Contractor Certification is a vote by the SMA Board of Directors.

SMA Events

The May meeting was, like all events, canceled. The SMA golf tournament is scheduled for October 19, and we still plan to hold that event. Sponsorship is available, and should the event be canceled, your sponsorship monies would be returned. Our next member meeting is scheduled for November 4. We are hoping that will take place.

Mark your Calendars for 2020

- October 19 – SMA Golf Tournament, Yorba Linda Country Club

- November 4 – SMA Membership Meeting, Yorba Linda Country Club

OSHA: Silica

While things seem sleepy, OSHA announced that they will go back to stricter enforcement of the silica rules in 2021. On June 25th OSHA sent out a memo to all inspectors in various states regarding silica dust.

While things seem sleepy, OSHA announced that they will go back to stricter enforcement of the silica rules in 2021. On June 25th OSHA sent out a memo to all inspectors in various states regarding silica dust.

OSHA INSTRUCTION NOTICE

Notice of intent required. States are expected to have accessible enforcement policies and procedures in place which are at least as effective as those in this Instruction.

The SMA urges contractors to get their people trained. You need a Competent Person, and the SMA offers “free” training. The SMA also offers a very short “Awareness” video for your employees. This is not full training and only lasts a few minutes. But it can prevent your employees from responding to the OSHA officer with a statement such as “ What is silica, my employer never told me a thing.” Statements like this are red flags to compliance officers. Protect yourself and your employees. In a short eight minutes, they can be aware of silica, and the SMA even has a 5 question test that all should be able to pass easily after watching the video. This can really help if OSHA wants to see what you have done to protect your worker. The cost for members is ZERO. So you really have no excuse.

THE CODE CORNER

The technical section developed to help SMA contractor members better understand, protect and run their business.\

The SMA has introduced some new Technical Bulletins on the website. Some are about clarifying the intent of the code, others are there to help with issues that come up with designers, general contractors, etc.

The SMA has introduced some new Technical Bulletins on the website. Some are about clarifying the intent of the code, others are there to help with issues that come up with designers, general contractors, etc.

The Bulletins are for members to use as third-party documentation that what you have proposed is either code compliant or good industry practice. The SMA encourages contractors to use the SMA to help you in these tough times.

Problem Job of the Month

The SMA gets calls all the time on stucco and stucco issues. This call came in from New York. The owner was concerned that he could find nowhere in any publication that a scratch and brown coat was applied to a cement board. He also could not find the use of a fiber mesh in lieu of using a lath.

The SMA gets calls all the time on stucco and stucco issues. This call came in from New York. The owner was concerned that he could find nowhere in any publication that a scratch and brown coat was applied to a cement board. He also could not find the use of a fiber mesh in lieu of using a lath.

After a discussion on the phone, the plasterers told him that they do this all the time. They plan to put ¾ inch of cement plaster on the cement board. The SMA asked if a picture could be sent. Our staff was certain the building owner did not know what he was talking about. No plasterer would do this.

The picture came in and, yes, these guys not only planned, but were doing it. Apparently they told him, “What’s the difference, cement over CMU or cement board, same thing.”

They did not appreciate the SMA response, but our job is quality stucco not appeasing bad practices that lead to stucco failures. This was removed and the plasterers were let go. The owner found a qualified stucco installer who did it right.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Fall 2019 eNews

FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

Fall is upon us, and winter is fast approaching. For those in the stucco industry and not in the south, it also means you need to pay attention to the weather. Frozen materials may be chemically altered and create real problems. It is useful to remember that ASTM C-926-19 requires cement plaster be applied when the ambient air temperature is higher than 40° F (4.4°C), unless the work area is enclosed and heat provided (Section 7.9.3.2). Plaster shall also not be applied to frozen surfaces or a base containing frost. Plaster shall not contain frozen ingredients and protected from freezing for a period not less than 24 hours after set has occurred (Section 7.9.1)

Acrylic finish coats cure like cement. However, the SMA thinks of them as drying more than curing. The acrylic finish can form a hard outer shell and appear to be set. Some plasterers have made the mistake to pull down the scaffold and tenting as soon as the acrylic is hard. However, it must be made sure that the acrylic is cured and adhered to the base coat. If the protection is removed too soon, the first rains will likely cause blisters and delamination issues.

SMA ONLINE EDUCATION/TRAINING

The SMA on-line training program is still underway. We have contracted with a professional firm for translation into Spanish. The program will be released before 2020 arrives. Some contractors have expressed concerns about the program. Any contractor member is invited to participate in the review of the program. In fact, we strongly encourage more feedback. This is a national program and tries to include all regions and be inclusive of regional differences. The cost of the program has not been finalized by the board of directors, but they are well aware it must be affordable to all. The thought to provide the class for free is still on the table. However, if certification is desired, the workload would be substantial for the SMA and added staff would need to be paid. The intent of the program is to ensure the installers “do no harm” when installing lath and stucco. Stucco is an excellent cladding when installed with basic care and understanding of the system. Please see our introductory video [in the sidebar at right] for a preview.

SMA NOVEMBER 6 MEETING — REGISTER ONLINE NOW

The next meeting for the SMA is November 6 at the Yorba Linda Country Club. [Register here] The speaker is Jacob Belk. Mr. Belk is a renowned forecaster of the residential construction economy. He worked at the Governor’s office, preparing industry forecasts to predict tax revenues, and is well respected for his advice. He spoke last year to the SMA and was well received by the members. He provided handouts that members have used all year to forecast and plan their businesses. His research is undeniably some of the best in the industry. The SMA has been working with Mr. Belk and is happy he feels we are a valued resource as well. His focus is on California, but other areas can learn from his presentation as well. The meeting and lunch start at noon on November 6.

The next meeting for the SMA is November 6 at the Yorba Linda Country Club. [Register here] The speaker is Jacob Belk. Mr. Belk is a renowned forecaster of the residential construction economy. He worked at the Governor’s office, preparing industry forecasts to predict tax revenues, and is well respected for his advice. He spoke last year to the SMA and was well received by the members. He provided handouts that members have used all year to forecast and plan their businesses. His research is undeniably some of the best in the industry. The SMA has been working with Mr. Belk and is happy he feels we are a valued resource as well. His focus is on California, but other areas can learn from his presentation as well. The meeting and lunch start at noon on November 6.

‘STUCCO LIVE’ RETURNS: Las Vegas, February 4-7, 2020

The SMA will again be hosting STUCCO LIVE at the World of Concrete in 2020. STUCCO LIVE 2019 was a great success — and special thanks to our friends at the Operative Plasterers & Cement Masons International Association (OPCMIA). The live demonstrations garnered large crowds to witness the pros at lath and plastering applying their craft. The skill was on display and the audience loved it. This year we’ll have live demonstrations highlighting various manufacturers’ products and systems. The show is February 4-7 at the Las Vegas Convention Center. The 2019 event had record attendance, and 2020 promises to be even bigger.

The SMA will again be hosting STUCCO LIVE at the World of Concrete in 2020. STUCCO LIVE 2019 was a great success — and special thanks to our friends at the Operative Plasterers & Cement Masons International Association (OPCMIA). The live demonstrations garnered large crowds to witness the pros at lath and plastering applying their craft. The skill was on display and the audience loved it. This year we’ll have live demonstrations highlighting various manufacturers’ products and systems. The show is February 4-7 at the Las Vegas Convention Center. The 2019 event had record attendance, and 2020 promises to be even bigger.

SMA GOLF 2019

Our annual golf tournament held on September 23 was another success. The Yorba Linda Country Club opened its brand new greens, and the course was in fantastic shape. Thank you to sponsors that make it all happen: Atlas Foam, Thompson Building Materials, La Habra Stucco, Merlex Stucco, Omega Products, Quikrete, CalPortland Cement, and PW Gillibrand Specialty Aggregates.

SMA BOARD OF DIRECTORS ELECTION

The SMA will soon be holding elections for an opening on the SMA Board of Directors. All members are eligible to serve. If you have the interest to serve on the SMA board, contact Mark Fowler at Mark@stuccomfgassoc.com. Being on the SMA board requires a commitment to time, and it is a responsibility not to be taken lightly. The SMA board implements plans and projects to better the overall stucco industry for the United States. It is not a platform to gain an edge on your competitors or focus on a single region of the country. The SMA board has an impeccable reputation as being fair and equitable for all. The SMA is blind to conflicts between signatory, merit even double-breasted shops. The Board is comprised of manufacturers, suppliers and contractors. This makes the SMA board unique in that the full industry is represented, nationally, and that we specialize only in lath and plastering.

Feature Articles

ASR — BEWARE

I have always said that plastering is a skilled craft; it requires trade skills and the knowledge that only the experience of working with it can bring. Unfortunately most of the experience that sticks with me is the witnessing of certain failures. This is why networking is so valuable to skilled trades. You can learn from others. ASR is an example and I had no idea what it was, and since working in the terrazzo side, it is a whole new world that stucco people should be cautious. ASR stands for Alkali Silica Reaction. It is known in the concrete industry as “concrete cancer.” It is a swelling reaction that occurs over time between highly alkaline cement paste and the reactive non-crystalline silica found in some aggregates, given sufficient moisture.

The chemical reaction is extremely complex. In simple terms, the cement paste can attack the siliceous aggregate converting the poorly crystallized or amorphous silica to a soluble alkali silicate. This, in turn, expands and then coverts the gel to solid calcium silicate hydrate. This expansive pressure increases in the core of the aggregate. The accumulated pressure can result in cracks to the aggregate and the surrounding cement paste. The problem is known worldwide, and we in the stucco business should be paying attention. The terrazzo industry has noted the condition and taken steps to prevent this issue of ASR. Portland cement and quartz sand, the aggregate we use, are rarely a problem. ASR has become more noticeable when designers opted for “glass” aggregates over the more traditional marble chips. The industry now recommends to the designer to stay away from glass aggregate.

The chemical reaction is extremely complex. In simple terms, the cement paste can attack the siliceous aggregate converting the poorly crystallized or amorphous silica to a soluble alkali silicate. This, in turn, expands and then coverts the gel to solid calcium silicate hydrate. This expansive pressure increases in the core of the aggregate. The accumulated pressure can result in cracks to the aggregate and the surrounding cement paste. The problem is known worldwide, and we in the stucco business should be paying attention. The terrazzo industry has noted the condition and taken steps to prevent this issue of ASR. Portland cement and quartz sand, the aggregate we use, are rarely a problem. ASR has become more noticeable when designers opted for “glass” aggregates over the more traditional marble chips. The industry now recommends to the designer to stay away from glass aggregate.

Why is this important to us?

Silica dust exposure was, and still is, a concern to plastering. It might seem a logical next step to consider switching to a recycled glass as a substitute. Glass is made of sand and, essentially, also a silica. But this silica is chemically altered when it is turned to glass, making the dust not a crystalline silica. Since ground glass is not a crystalline silica, this could tempt some to replace this glass over traditional quartz sand, which is crystalline silica and falls under the OSHA rules. We should be careful about jumping to solutions without vetting all the ramifications.

SNAPSHOT OF THE ECONOMY

The FMI Third Quarter 2019 North American Engineering & Construction Outlook has released its report on the economy. This report features comprehensive construction forecasts for the U.S. and Canada as well as information on key market drivers. Contact the SMA office if you would like a copy of the FMI report.

Key highlights of the report include:

- Total engineering and construction spending for the U.S. is forecast to end up <1 percent in 2019, compared to up 3 percent in 2018.

- U.S. spending growth in 2019 is expected to be led by public investment across both nonresidential buildings and nonresidential structures. Current top-performing segments forecast in 2019 include conservation and development (+10 percent), water supply (+9 percent), public safety (+9 percent), transportation (+8 percent) and sewage and waste disposal (+8 percent).

- Only one U.S. segment was upgraded into our growth category through the second half of 2019, lodging. On the other hand, the commercial market was the only segment downgraded, from stable to down. Despite stable fundamentals, all three residential segments continue to show weakness and are expected to end this year below 2018 spending levels.

- FMI’s Nonresidential Construction Index (NRCI) at 50.4 is the lowest score recorded in more than seven years. An index score over 50 suggests improving or expanding industry conditions.

- Several of Canada’s segments, including conservation and development, power, public safety, sewage and waste disposal, and water supply, were upgraded into our growth category through the second half of 2019. In contrast, the lodging and office segments were downgraded from growth to down.

US CENSUS DATA: Privately owned housing starts in September 2019 were at a seasonally adjusted annual rate of 1,256,000. This is 9.4 percent (+/- 9.4%) * below the revised August 2019 estimate of 1,386,000.

Snapshot on US Housing Starts :

- September 2019: -9.4* % change

- August 2019 (r): +15.1 % change

ASTM NEWS

ASTM C 1861 is the new ASTM that pulled trim accessories out of the old ASTM C 1063. This ASTM goes into detail on the specifications for the trims used in cement plaster. Several pages are dedicated to illustrations of trims used in plastering and a name assigned to each trim. Table 3 covers the Fasteners and the length required to attach the various trims to framing members. Table 1 covers minimum thickness required for the trim accessory. Table 2 is for Cold-rolled Channel Furring.

ASTM C 1861 is the new ASTM that pulled trim accessories out of the old ASTM C 1063. This ASTM goes into detail on the specifications for the trims used in cement plaster. Several pages are dedicated to illustrations of trims used in plastering and a name assigned to each trim. Table 3 covers the Fasteners and the length required to attach the various trims to framing members. Table 1 covers minimum thickness required for the trim accessory. Table 2 is for Cold-rolled Channel Furring.

ASTM C 1860 is also new. For decades there was no test to verify the bond of cement plaster to masonry or to itself. ASTM C 1860 addresses this. This is a test method with procedures to determine the tensile strength of Portland cement-based plaster. The test is appropriate for new and existing construction if the plaster has been in place a minimum of 28 days. This is a bonding test and not intend to evaluate the underlying construction or framing the test methods are intended to be used as a tool to quantitatively evaluate the existing Portland cement plaster cladding that is suspected of questionable bond or uncertain fastening to the substrate. Test method A and B are essentially cut squares where the stucco is pulled off the wall. The SMA is still evaluating the value and how it will ultimately impact the stucco industry. This may be more about how it is used, by whom and for what purpose.

PLEASE NOTE: SMA OFFICE CONTACT INFORMATION

Mark Fowler, Executive Director

Marlene Lampert, Office Manager

Stucco Manufacturers Association

5753 E Santa Ana Cyn Rd, Suite G-156

Anaheim, CA 92807

Office: 714-473-9579

Mark@stuccomfgassoc.com

Marlene@stuccomfgassoc.com

REMEMBER: The SMA has a fairly large library on all things stucco. Members of the SMA are encouraged to call the SMA office if the staff can be of any assistance.

Summer 2019 eNews

MESSAGE FROM THE SMA EXECUTIVE DIRECTOR

Mark Fowler, SMA Executive Director

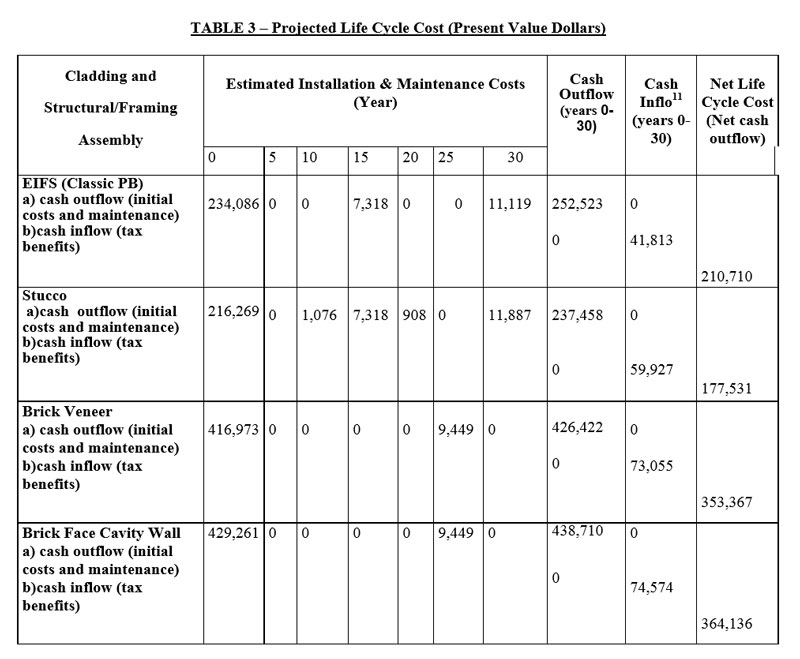

Hope everyone is looking forward to a great summer. The SMA has a lot happening. We have released the 2019 Stucco Market Report. The first industry report was in 2016 and was used extensively around the United States. The report gained respect as accurate and insightful, as being specific and targeted to our industry. The SMA was invited to the World of Concrete to demonstrate STUCCO LIVE in large part due to the 2016 Stucco Market Report. The 2019 updated version will continue this trend as it is based on data from the US Census Bureau and other market research groups. The SMA takes that data and combines it with our knowledge and can make several observations. The report is a free download at the SMA website.